Rayka Condensing Boiler Catalog Download

Catalogue for All Capacities

Hydraulic Separator Catalog Download (Low Loss Header)

Low Loss Header Selection for Condensing Boiler

Packman General Catalogue Download

All Packman Product Catalogue

P 1

In the construction of Rayka condensing boilers, stainless steel 316L tubes are used according to ASTM A269 standard, which has very high resistance to heat and water acidity. This material prevents corrosion in the smoke condensation process.

Available on backorder

Catalogue for All Capacities

Low Loss Header Selection for Condensing Boiler

All Packman Product Catalogue

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

The construction of Rayka Packman condensing boilers is carried out in accordance with ASME standards.

Additionally, all parts related to the pressure components comply with comprehensive ASME codes

Furthermore, all materials used in the heat exchanger are selected according to ASTM requirements.

The construction of Rayka condensing boilers is carried out using tubes from the 300 series of stainless steel (Austenitic Stainless Steel 3xx Series). Due to the presence of nickel and chromium, it is a material resistant to the operating conditions of the boiler. Stainless Steel 316L alloy is the most resistant alloy to acidic corrosion. This acid is generated from the operation of the condensing boiler.

The main reason for the high efficiency of this boiler is the condensation created within the boiler. One of the few alloys resistant to this condensation at high temperatures is 316L Stainless Steel. Due to the presence of nickel and chromium, the material is resistant to the operating conditions of the boiler.

The efficiency of Rayka Packman condensing boilers is based on a high-efficiency combustion system, reaching up to approximately 98.9% in HHV (depending on the relative humidity of the ambient air). This is according to Chapter 32 of the ASHRAE-HVAC System & Equipment Handbook, 2012 edition, which represents the highest level of efficiency for condensing boilers.

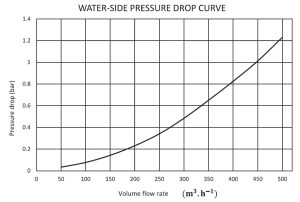

These boilers are designed with a lower water volume compared to three-pass firetube hot water boilers, which categorizes them as Low Mass boilers, similar to other condensing boilers manufactured worldwide. This boiler can operate within the appropriate range for building design in terms of the temperature differential between supply and return, which may require the use of primary-secondary loop for system balance. You can download the catalog related to hydraulic separators and this boiler tab for more information.

To view the video related to the Packman condensing boiler, click here.

| Weight | 6200 kg |

|---|---|

| Dimensions | 3800 × 2450 × 3000 mm |