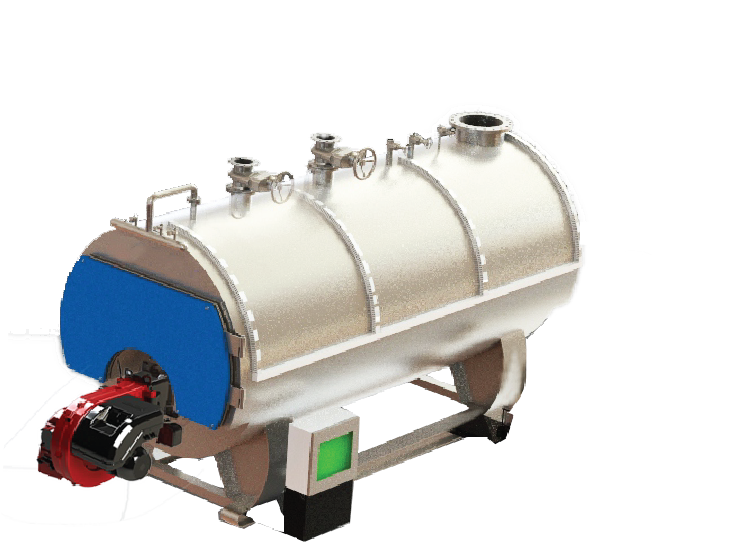

Hot Water

Condensing

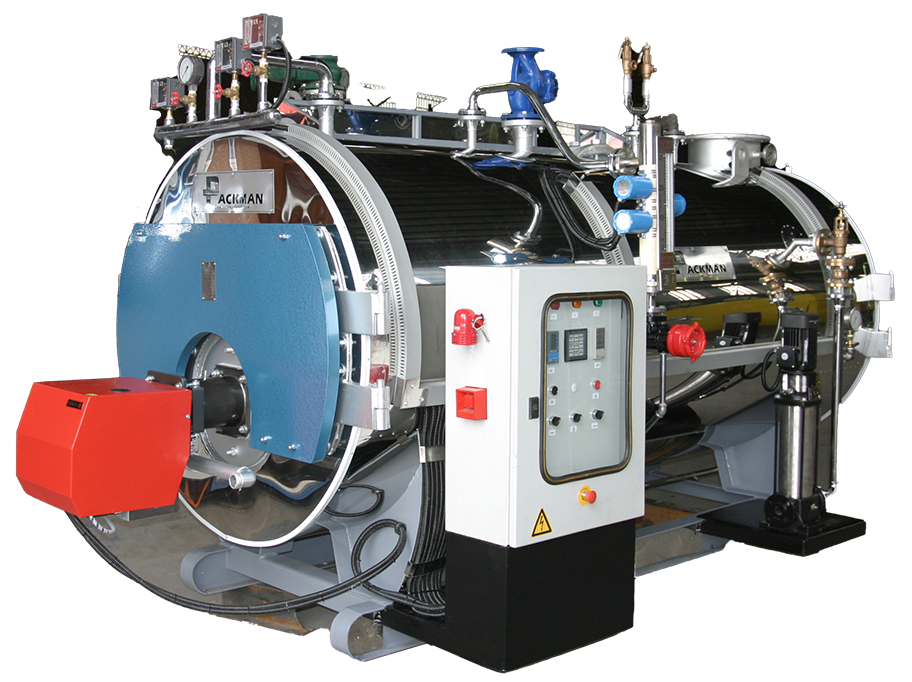

Boiler

Consumables and Equipment

High-quality European standard materials are used in the construction of boilers to increase the lifespan of the device.

Engineering & Designing

Designing state-of-the-art products is accomplished through modern technical knowledge and fluid and solid analysis.

Manufacturing, Production, and Technology

Manufacturing equipment with the latest production facilities such as CNC pipe bending machine, boiler tube manufacturing and grooving, robotic welding, and more is possible.

After Sales Service

24-hour after-sales services are available in all cities of Iran to launch and ensure customer satisfaction.

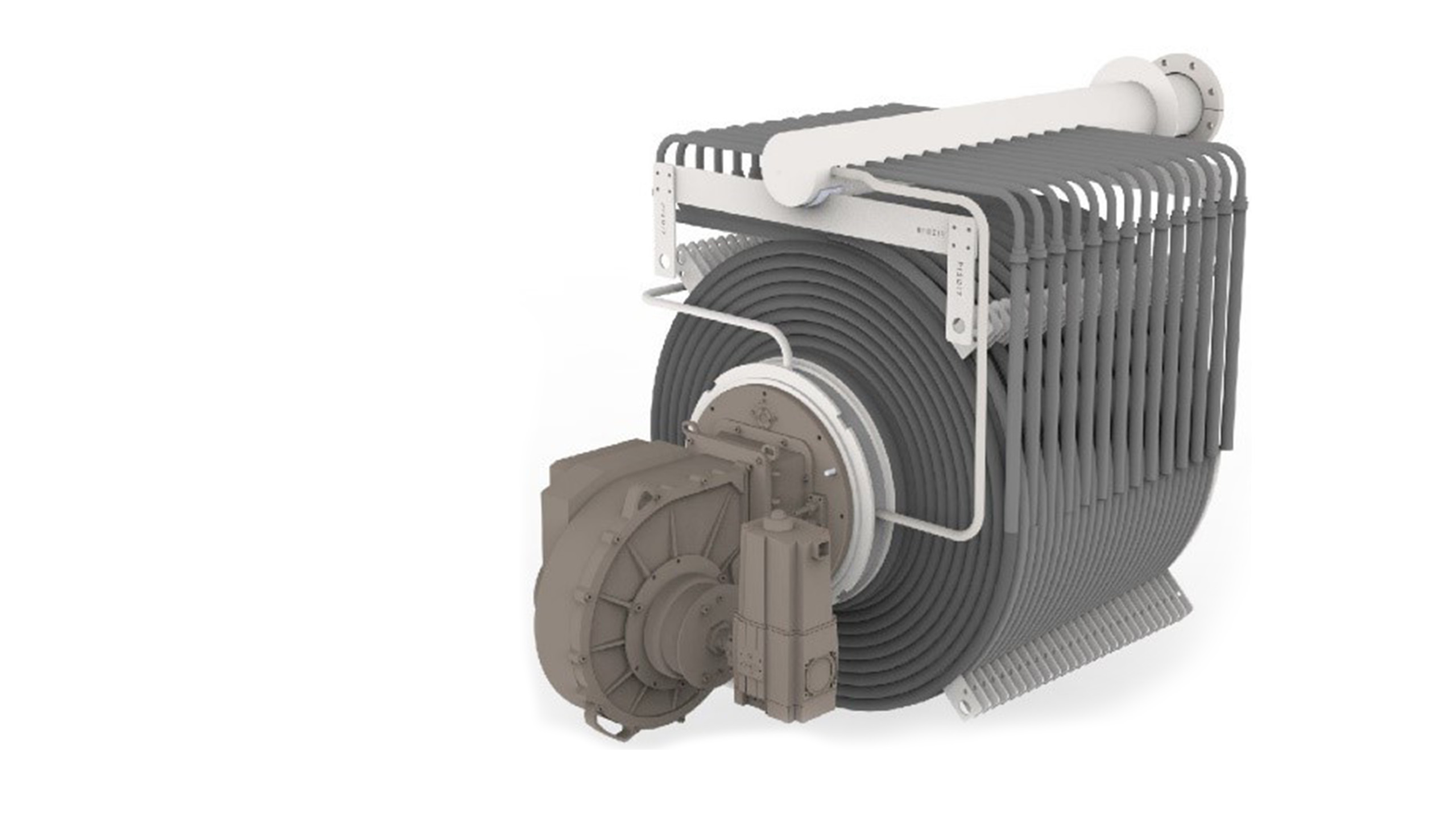

Cross-sectional view

Cross-sectional view

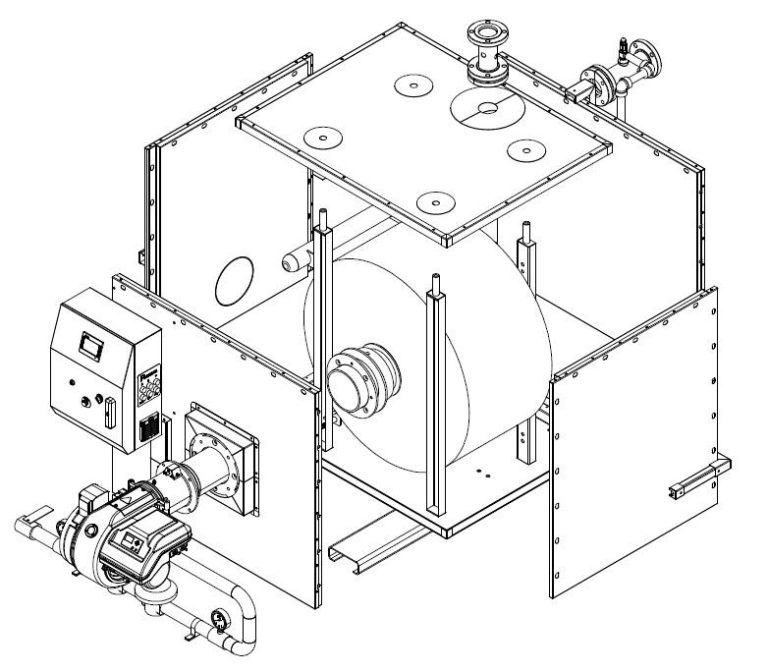

Completion facade

Completion facade

into English is "Structure of Packman Condensing Boilers.

Packman Condensing Boilers are available in three types: Rayka, Atrisa, and Optima, capable of operating up to 85 degrees Celsius, and have two types of fuel: gas and dual (gas-oil) according to customer request. This boiler is based on an advanced combustion system, producing hot water with 98% efficiency. In a condensing boiler, the goal is to heat water using latent energy in the steam produced by combustion products. This energy is transferred to the input water through a phase change, and the energy is returned to the boiler.

In the construction of these boilers, all tests have been conducted in accordance with the procedures specified by the American National Standard Institute (ANSI). Moreover, all sections related to the Pressure Part are in accordance with the regulations of the American Society of Mechanical Engineers (ASME). All materials used in the heat exchanger are selected in accordance with the requirements of the American Society of Testing Materials (ASTM).

Density boilers have a wide range of applications and a wide range of uses. These applications include hotels, office towers, residential complexes, hospitals, universities, schools, warehouses, public swimming pools, and so on.

- Spiral Pipe Technology

- Intelligent control system of hardware type

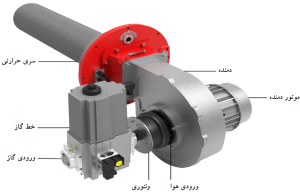

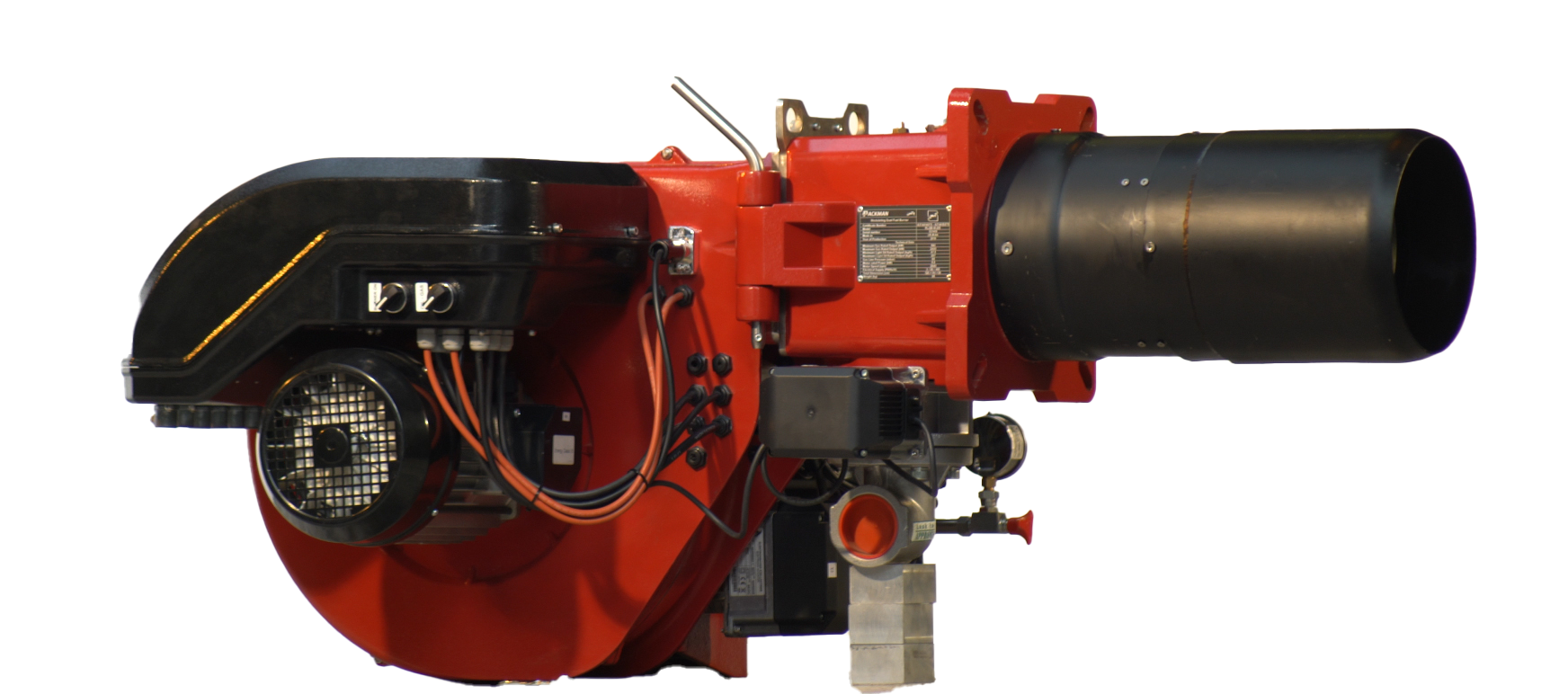

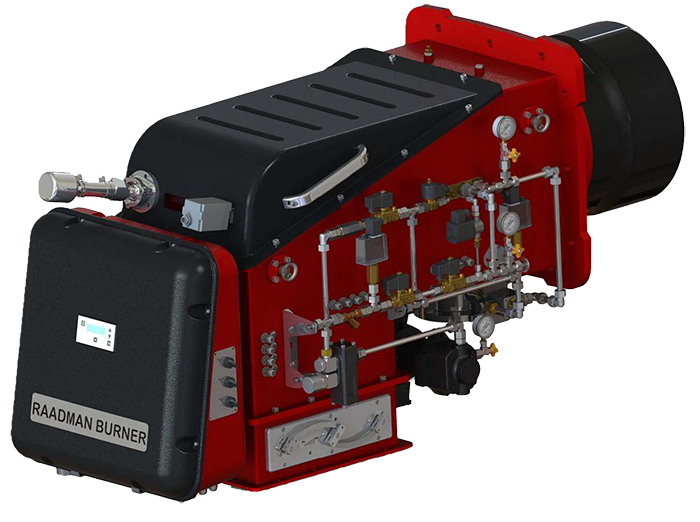

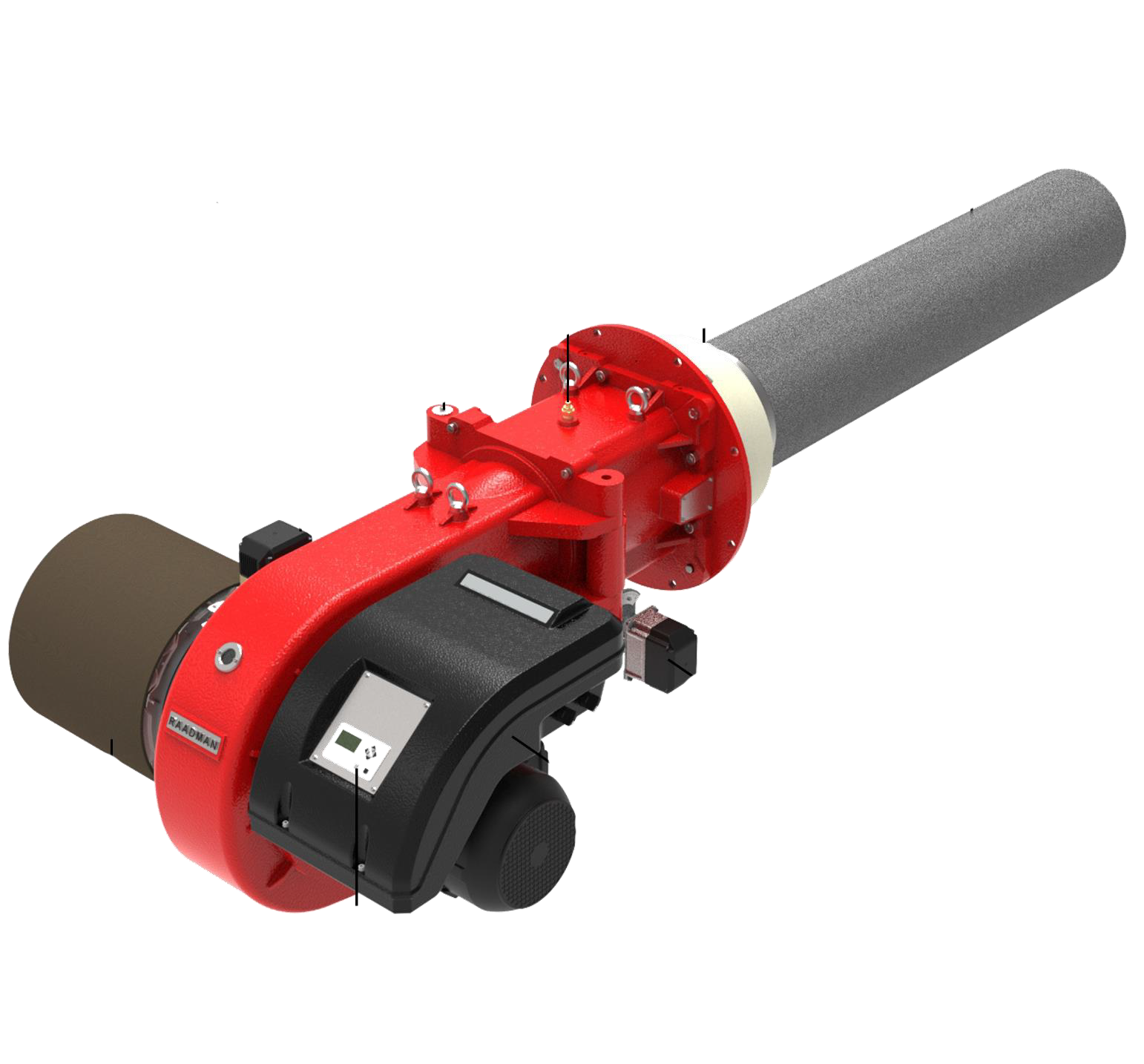

- The electronic modular burner Raadman

- Ability to control with ambient temperature.

Build your solution.

Design engineering consultation, procurement, and manufacturing of your power plant equipment entrusted to us.

Tube welding machine and boiler manufacturing.

Some of the structural and design features of Packman condensing boilers.

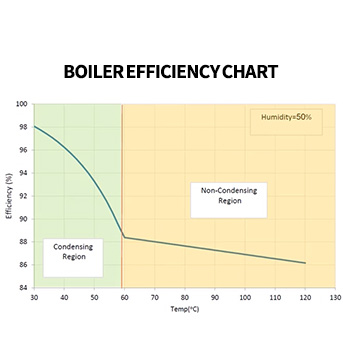

The efficiency of the condensing boiler varies based on the return water temperature to the boiler and the load of the burner. In such a way that at an inlet water temperature of 30 degrees Celsius or lower and operating at less than 30% of the boiler capacity, it achieves the highest efficiency, which is 98%. This performance is based on HHV.

The performance chart of the boiler in two states: condensing and non-condensing.

consumable materials

Optimized condensing boilers from Pakman company range from 100 to 600 kilowatts.

To receive the catalog of Pakman company's condensing boilers, please click.

Frequently Asked Questions

Some frequently asked questions have been set up for your convenience in selecting and obtaining further information. If you have further questions, please contact the technical department of the company.

?

Yes, due to the fact that these boilers have a lower water holding capacity compared to three-pass fire tube boilers, to prevent water and air blockage in the boiler pipes, we need to create secondary flow in these boilers using header distributors.

both yes and no.

Boilers are expressed in terms of LHV (Lower Heating Value) and HHV (Higher Heating Value) efficiencies. The efficiency figure of 108% is based on the lower heating value or LHV, which is higher than 100% because it accounts for the latent heat of vaporization subtracted from the input energy, making the resulting figure higher than 100%. It should be noted that this index number will not indicate energy consumption.

No, condensing boilers are in their best condition when the inlet water temperature to the boiler is around 30 degrees Celsius, and the burner capacity is at its minimum, achieving the highest efficiency. This efficiency is not maintained when the inlet water temperature to the boiler is higher. But the minimum efficiency of condensing boilers is 90 percent in the worst case.

The flue gas boiler can be released into the environment and can have a low height, but depending on the capacity, it can be higher, but its diameter depends on the friction rate of the flue gas material, the volume of combustion products, the barometric pressure of the city where it is installed, the momentary pressure of the combustion products exiting the nozzle, and the relevant fluid velocity, which should be contacted with the technical department of Packman Company for this.

Need for

Do you need advice?

Do you know if you have free engineering consultancy and services on Packman products?

Boiler

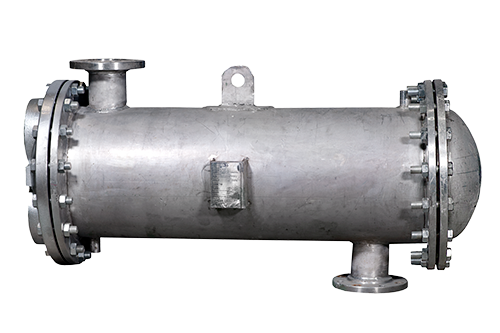

Boiler Heat Exchanger

Heat Exchanger Pressure Vessel

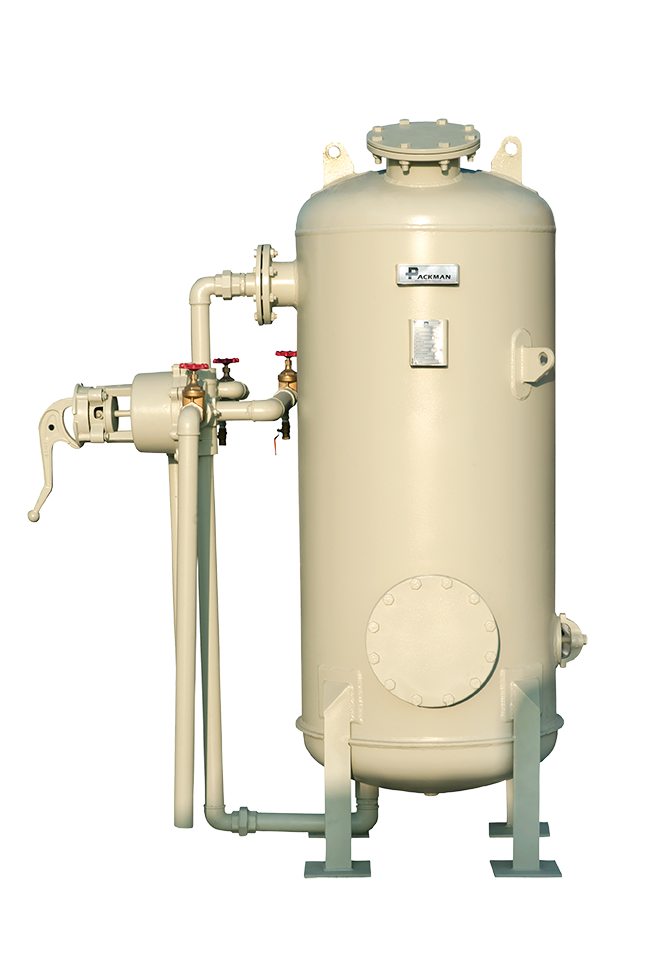

Pressure Vessel Storage Tank

Storage Tank Scroll Aircooled Chiller

Scroll Aircooled Chiller Screw Aircooled Chiller

Screw Aircooled Chiller Air Handling Unit

Air Handling Unit Fancoil

Fancoil Mono Block Burner

Mono Block Burner Dual Block Burner

Dual Block Burner Pre Mix & Semi Pre Mix Burner

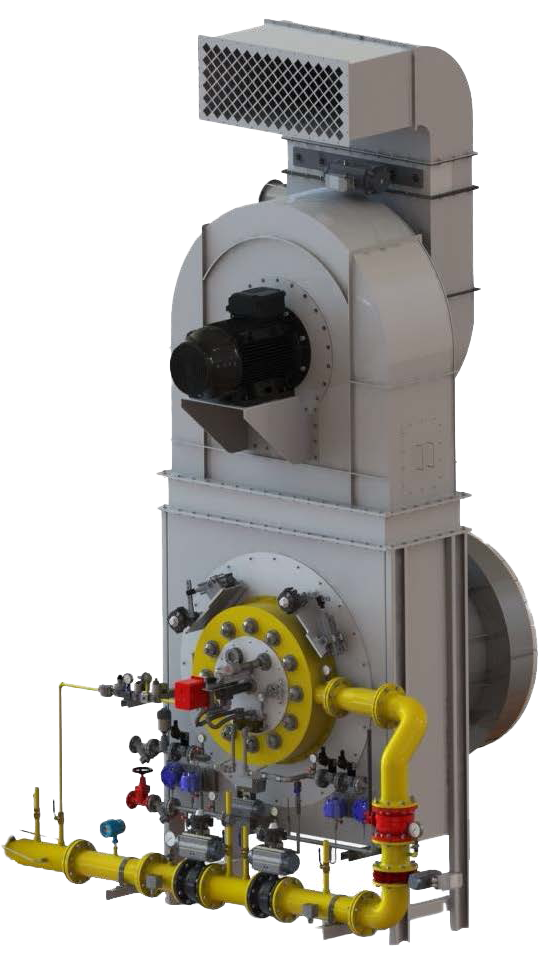

Pre Mix & Semi Pre Mix Burner Power Plant Burner

Power Plant Burner RO Water Desalination

RO Water Desalination Water Physical Filter

Water Physical Filter ION Exchange Filter

ION Exchange Filter Chemical Dosing Package

Chemical Dosing Package Heatco

Heatco Transheat

Transheat Planta

Planta Reco

Reco