Introducing the book Condensing Boiler Theory & Function.

The book ‘Theory and Function of Condensing Boilers’ has been published. This book serves as a guide in the field of condensing boilers.

Introduction

This book is the result of compiling the experiences of Packman Company, with over half a century of experience, dedicated to expanding the building services industry, especially in the manufacturing, production, and optimization of boilers. By using modern methods and extensive experience in various projects, the company has not only published several books and technical booklets but also registered numerous inventions.

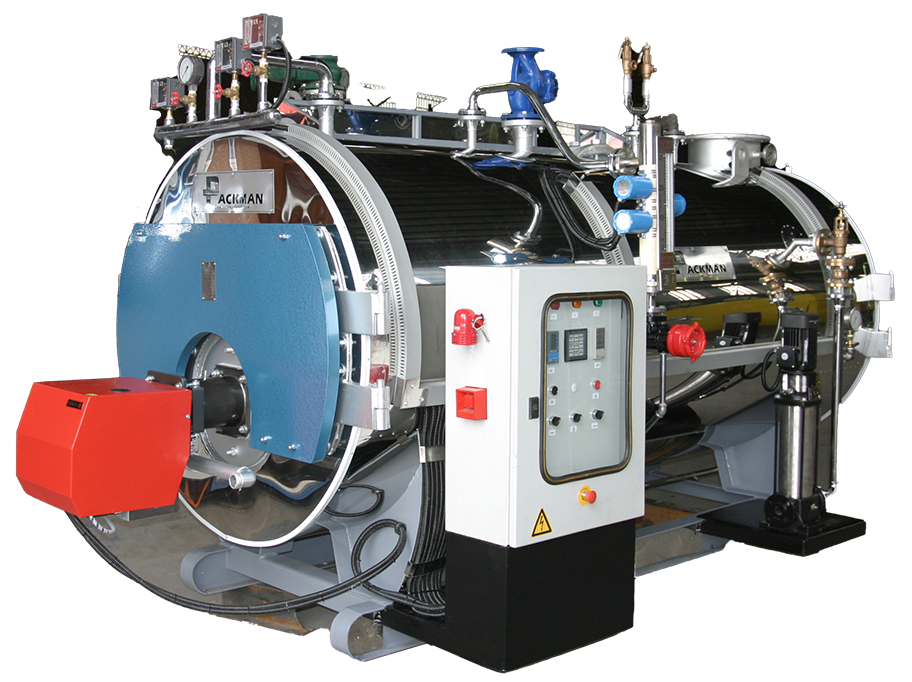

Condensing boilers, package boiler rooms, water packs, fire-tube boilers, and water-tube boilers are among the products localized by Packman Company.

Packman’s research department has spent over 3,000 hours of engineering work to compile this book, drawing on these experiences, aiming to present the theory and application of condensing boilers. Below, the subject matter of the book is discussed.

About the Book

The increasing global warming, urban pollution, depletion of fossil fuel reserves, and dozens of similar keywords have become concerns not only for environmental activists and policymakers but also for many other stakeholders, including engineers in the building services industry.

Given the high consumption of fuel and environmental pollution from engine rooms, especially in densely populated cities, increasing the efficiency of heating and cooling systems is one of the most important concerns in today’s engineering communities.

Condensing boilers, with the ability to increase the maximum efficiency of traditional boilers up to 98%, are one of the main solutions for reducing fuel consumption and pollution. For this reason, Packman’s R&D unit has focused on producing and developing various types of condensing boilers for 10 years, to the extent that today condensing boilers in three different types, with unique capabilities, are being produced in two separate factories.

Therefore, in order to optimize the use of knowledge of condensing boilers, we decided to write and publish a book called ‘Theory and Operation of Condensing Boilers,’ hoping that it may assist consultants, HVAC specialists, mechanical engineering students, and professors in designing optimal solutions and promoting comprehensive culture for using high-efficiency boilers in projects.

Writing this book is the result of the tireless efforts of the specialized scientists at Packman Company in the field of condensing boiler production, burners, and HVAC system design. They have gathered the materials by relying on their experience in boiler manufacturing and careful examination of relevant texts, extensive research on leading boiler manufacturers worldwide, and current articles. It is hoped that this book will help change perspectives and contribute to creating a brighter future.

Finally, I would like to express my deepest gratitude to Mr. Engineer Keyvan Ahmadi and Dr. Soroush Arshadi as the main collaborators of Packman Company in writing this book. Additionally, special appreciation is due to Mr. Soheil Mirzazadeh, Vahid Azizi, Ali Emadi, and Amir Shemshiri, who have put all their efforts into writing and integrating this book.

|

|

So look briefly to the Table of Content

|

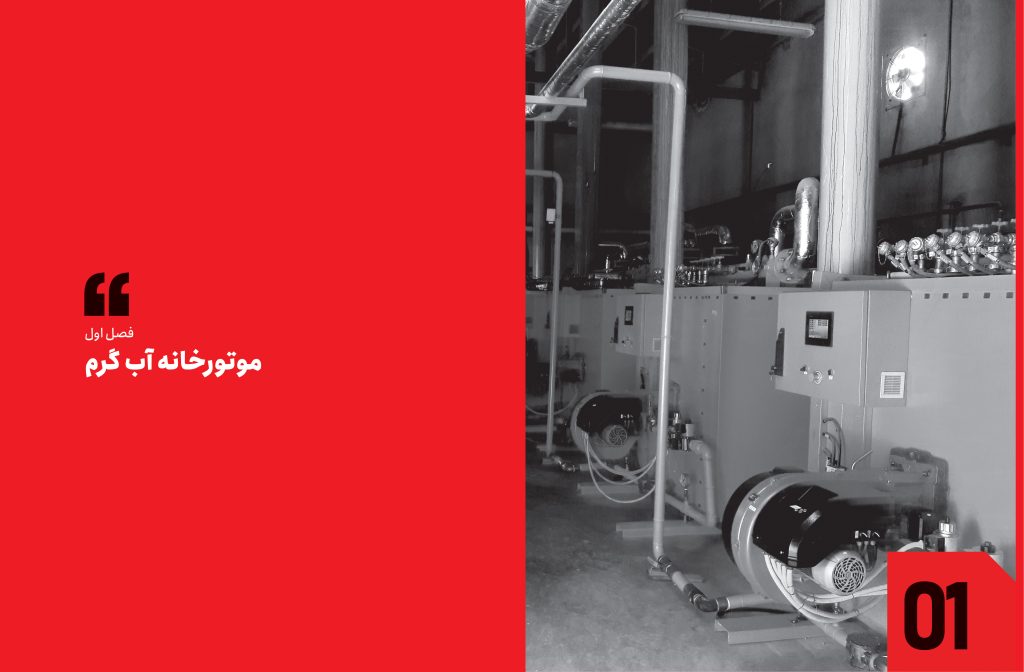

Chapter 1: Hot Water Boiler Room

1-1- Selecting the Appropriate HVAC System

1-1-1- System Constraints

1-1-1- Types of HVAC Systems

1-2- Central Boiler Room

1-3- Boiler

1-3-1- Fire-tube Boilers

1-3-1-1- Single Pass Fire-tube Boiler

1-3-1-2- Two-Pass Fire-tube Boiler

1-3-1-3- Reverse Flame Fire-tube Boiler

1-3-1-4- Three Pass Fire-tube Boiler

1-3-1-5- Four Pass Fire-tube Boiler

1-3-2- Water-tube Boilers

1-3-2-1- Water-tube Boilers with Straight Tubes

1-3-2-2- Water-tube Boilers with Bent Tubes

1-3-2-3- Water-tube Boilers Based on Circulation Type

1-3-3- Condensing Boilers

Conclusion

|

Chapter 2: Combustion

2-1- Definition of Combustion Phenomenon

2-2- Heat Produced by Combustion

2-3- Combustion Efficiency

2-4- Natural Gas and By-products of its Combustion

2-4-1- Methane Combustion Reaction

2-5- Neutralization of Combustion By-products

2-6- Iranian and International Standards for Combustion Products

|

Chapter 3: Condensation

3-1- Concept of Condensation

3-1-1- Gas Mixtures and Dew Point

3-1-2- Condensation Process and its Types

3-1-3- Effect of Gas Mixing on Dew Point

3-1-4- Thermal Resistances in Condensation Processes

3-1-5- Water Vapor in Combustion

3-1-6- Latent Heat of Water

3-1-6-1- Utilization of Latent Heat of Water

3-2- History of Condensation Use

3-3- Applications of Condensation in Various Industries

3-3-1- Thermal Distillation Processes

3-3-1-1- Multi-Stage Flash Distillation (MSF)

3-3-1-2- Multi-Effect Distillation (MED)

3-3-1-3- Vapor Compression Distillation (VC)

3-3-2- Condensers and Cooling Towers

3-3-3- Thermal Power Plants

3-3-4- Condensation Dryers

|

|

Chapter 5: Types of Condensing Boilers and Their Applications

5-1- Types of Condensing Boilers

5-1-1- Firetube Condensing Boilers

5-1-2- Watertube Condensing Boilers

5-2- Applications of Condensing Boilers

5-2-1- Building Heating (Green Buildings)

5-2-2- Medical Centers

5-2-3- Swimming Pools

5-2-4- Laundries

5-2-5- Car Washes

5-2-6- Food Industries

5-2-7- Electronics Manufacturing

5-2-8- Various Industries

|

Chapter 6: Requirements for Condensing Boilers

6-1- Requirements of the Boiler Room Environment

6-1-1- Availability of Air

6-1-1-1- Supply of Combustion Air from Indoor Environment

6-1-1-2- Supply of Combustion Air from Outdoor Environment

6-1-1-3- Supply of Combustion Air Using a Combination of Indoor and Outdoor Air

6-1-1-4- Supply of Air Using a Fan

6-1-2- Environmental Factors

6-1-3- Drainage

6-2- Placement of the Boiler in the Boiler Room

6-2-1- Minimum Distance for Boiler Access

6-2-2- Boiler Protection in Outdoor Environment

6-3- Recommended Equipment for Condensing Boilers

6-3-1- Gas Line Safety

6-3-2- Water Line Safety

6-3-3- Strainer and Filter

6-3-4- Flue Gas Vent

6-4- Requirements for Design and Installation of Flue Gas Vent

6-4-1- Flue Gas Vent Operation Principles

6-4-2- Necessary Calculations for Flue Gas Vent Design

6-4-3- Design Requirements for Flue Gas Vent

6-4-3-1- Draft Control

6-4-3-2- Wind Effect

6-4-3-3- Material Selection for Flue Gas Vent

6-4-3-4- Condensate Drain

|

Chapter 7: Pakman Condensing Boilers

7-1- Introduction

7-2- Technical Specifications of Pakman’s Rayka Series Condensing Boilers

7-3- Components of Rayka Series Condensing Boilers

7-3-1- Internal Parts of Heat Exchanger

7-3-2- External Parts

7-3-3- Valves and Control Devices

Optima Condensing Boiler User Guide

1- Boiler Specifications

1-1- Technical and Dimensional Specifications

2- Boiler Transport

2-1- Boiler Transportation

2-2- Access Space

3- Boiler Installation

3-1- Boiler Water Piping

3-2- Boiler Room Ventilation

3-3- Gas Piping

3-4- Flue Gas Vent

3-5- Condensate, Discharge, and Safety Valve Piping

3-6- Additional Installation Notes

4- Boiler Commissioning

4-1- General Considerations

4-2- Fuel and Burner Air Adjustment

4-3- Boiler Operation Status

4-4- Boiler Water Temperature Adjustment

5- Boiler Maintenance and Repair

5-1- Gas Line Filter Cleaning

5-2- Ion Rod and Ignition Spark Adjustment

5-3- Burner Series Cleaning

6- Troubleshooting

7- Boiler Equipment

7-1- Temperature Sensors

7-2- Temperature Controllers

7-3- Water Pressure Switch

7-4- Electrical Panel

|

Chapter 8: Requirements for Designing Boiler Rooms for Installing Packman Condensing Boilers

8-1- Introduction

8-2- Boiler Room Ventilation

8-3- Efficiency of Condensing Boilers

8-3-1- Seasonal Efficiency in Condensing Boilers

8-3-2- Control of Boiler Outlet Water Temperature

8-4- Proposed Flow Diagrams for Installation and Methods to Increase the Efficiency of Pakman Condensing Boilers

8-5- Hydraulic Separation in Condensing Boiler Rooms

1-5-8- Common Pipe

2-5-8- Header Pipes

8-6- Advantages of Using Pakman Condensing Boilers in Boiler Rooms

|

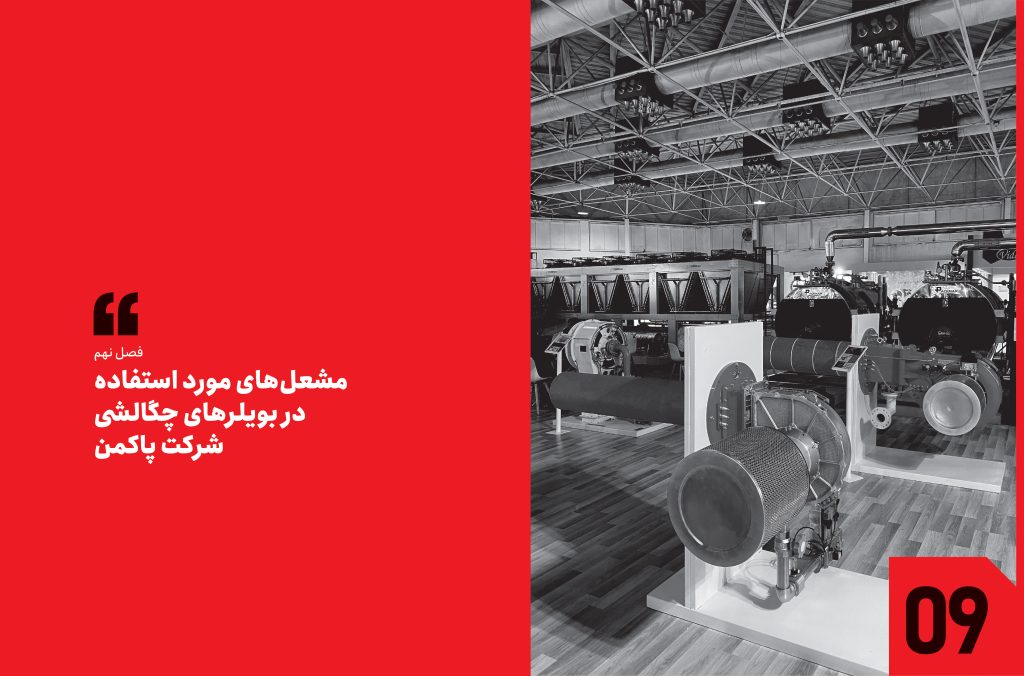

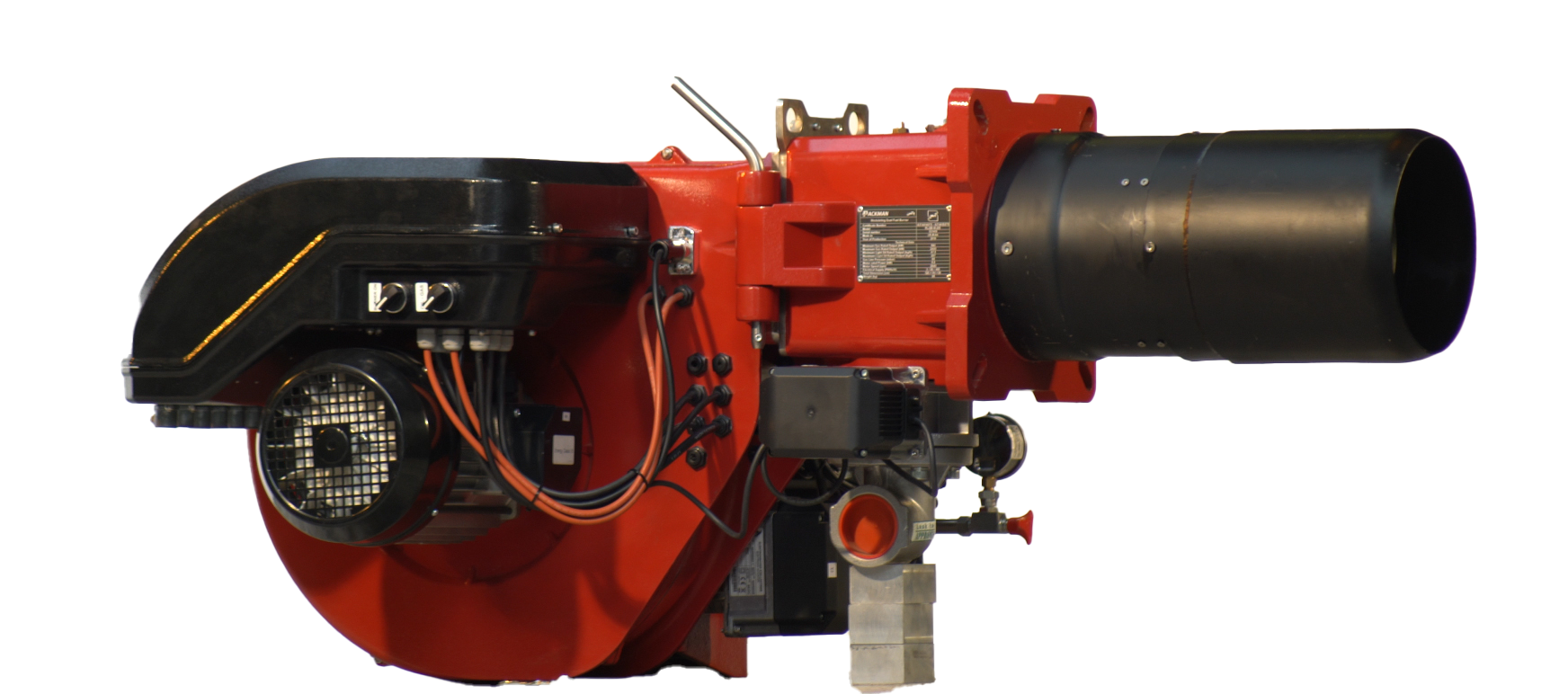

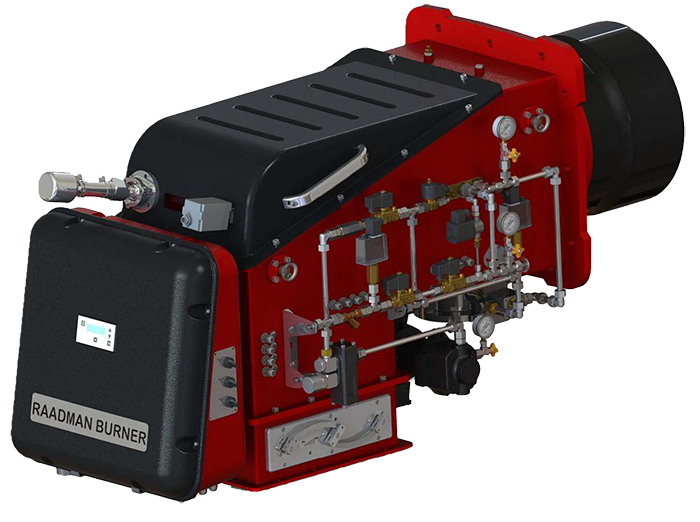

Chapter 9: Burners Used in Pakman Condensing Boilers

9-1- Introduction

9-1-1- Single Stage Burners

9-1-2- Two Stage Burners

9-1-3- Modulating Burners

9-1-3-1- Mechanical/Step Modulating Burners

9-1-3-2- Pneumatic (Proportional)/Step Two Modulating Burners

9-1-3-3- Electronic Modulating Burners

9-2- Formation of NOx

9-2-1- Thermal NOx Formation

9-2-1-2- Prompt NOx Formation

9-2-1-3- Fuel NOx Formation

9-3- Pollution Control in Burners

9-3-1- Limits of Carbon Monoxide and NOx Pollutants

9-4- Classification of Burners Based on Fuel-Air Mixing Method

9-4-1- Premix Burners

9-4-1-1- Air Damper

9-4-1-2- Burner Air Supply System (Blower)

9-4-1-3- Burner Ignition System

9-4-1-4- Flame Scanner

9-4-1-5- External Flame Shroud

9-4-1-6- Burner Safety Equipment

9-4-1-7- Electrical Panel

2-4-9- Premix Burners

9-4-2-1- Thermal Head

9-4-2-2- Air Supply System

9-4-2-3- Venturi

9-4-2-4- Gas Line in Premix Burners

9-4-2-5- Flame Scanner

9-4-2-6- Control System

9-4-3- Post-mix Burners

9-4-3-1- Thermal Head

9-4-3-2- Fuel and Air Mixer

9-4-3-3- Air Supply System

9-4-3-4- Filter

9-4-3-5- Control System

9-4-3-6- Fuel Delivery System

9-4-3-7- Flame Scanner

9-5- Gas Line in Gas Burners

9-5-1- Required Equipment in Gas Line

9-5-1-1- Filter/Strainer

9-5-1-2- Regulator/Governor

9-5-1-3- Pressure Cut-off Valve

9-5-1-4- Safety Valve

9-5-1-5- Minimum Pressure Control Key

9-5-1-6- Maximum Pressure Control Key

9-5-1-7- Leak Detection System

9-5-1-8- Safety Gas Valve

9-5-1-9- Main Gas Valve

9-5-1-10- Butterfly Valve

9-5-1-11- Pilot Line

9-6- Calculation of Gas Line Inlet Pressure for Maximum Operation

9-7- Diesel Fuel Line

9-7-1- Diesel Fuel Filter

9-7-2- Diesel Fuel Pump

9-7-3- Diesel Fuel Return Pressure Regulator

9-7-4- Minimum Pressure Control Key

9-7-5- Fuel Safety Valve

9-7-6- Main Fuel Valve

9-7-7- Fuel Injection Nozzle

9-7-8- Lens

9-8- Control System in Modulating Burners

9-8-1- Pneumatic Modular Burners

9-8-2- Electronic Modular Burners

9-9- Burner Performance

9-10- Selecting a Burner Suitable for Boiler Capacity

|

Chapter 10: Electrical and Electronic Systems in Pakman Condensing Boilers

10-1- Introduction

10-2- Functions of Boiler Electrical Panel

10-3- Set Point Adjustments

10-3-1- Fixed Set Point

10-3-2- Variable Set Point with Ambient Temperature

10-4- Equipment Used in Boiler Electrical Panel

10-4-1- Pt100 Sensor (Single Probe)

10-4-2- Pt100 Sensor (Dual Probe) (Outlet Water Temperature)

10-4-3- Pressure Transmitter

10-4-4- Current Switch (Flow Switch)

10-4-5- Augstats

10-4-6- Boiler Electrical Panel

10-4-7- Safety Components of Electrical Circuit

10-4-8- HMI and PLC

10-5- Boiler Electrical Panel Display Screen

10-6- Installation and Maintenance Tips for Boiler Electrical System

Chapter 11: Performance of Pakman Condensing Boilers

11-1- Introduction

11-2- Stages of Simulation and Numerical Analysis

11-3- Simulation of Pakman Condensing Boilers

11-3-1- Simulation and Analysis of Heat Exchanger

11-3-1-1- Solution Domain Geometry

11-3-1-2- Mesh Generation

11-3-1-3- Governing Equations

11-3-1-4- Boundary Conditions

11-3-1-5- Numerical Solution

11-3-1-6- Results Analysis

11-3-2- Simulation of Water Flow Inside Pipes

11-3-2-1- Solution Domain Geometry

11-3-2-2- Mesh Generation

11-3-2-3- Governing Equations

11-3-2-4- Boundary Conditions

11-3-2-5- Numerical Solution

11-3-2-6- Results Analysis

11-3-2-7- Pressure Drop vs. Flow Rate Curve

Thesis

References

PACKMAN Company Profile

Other Book Specifications:

Title and Author: Theory and Operation of Condensing Boilers / Ghorbanali Mirzazadeh

Publication Details: Tehran: Towangaran Pouya, 2023.

Physical Description: 365 pages. ISBN.

Cataloging Status: FIPA

Subject: Condensing Boilers

Bibliographic Record Information: FIPA

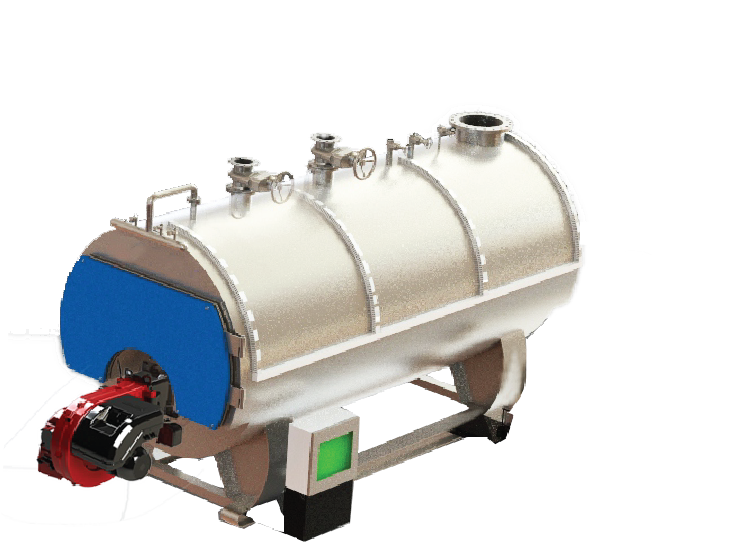

Boiler

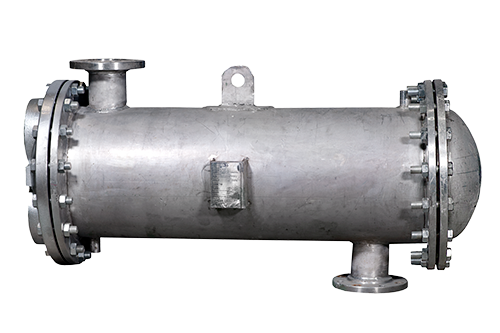

Boiler Heat Exchanger

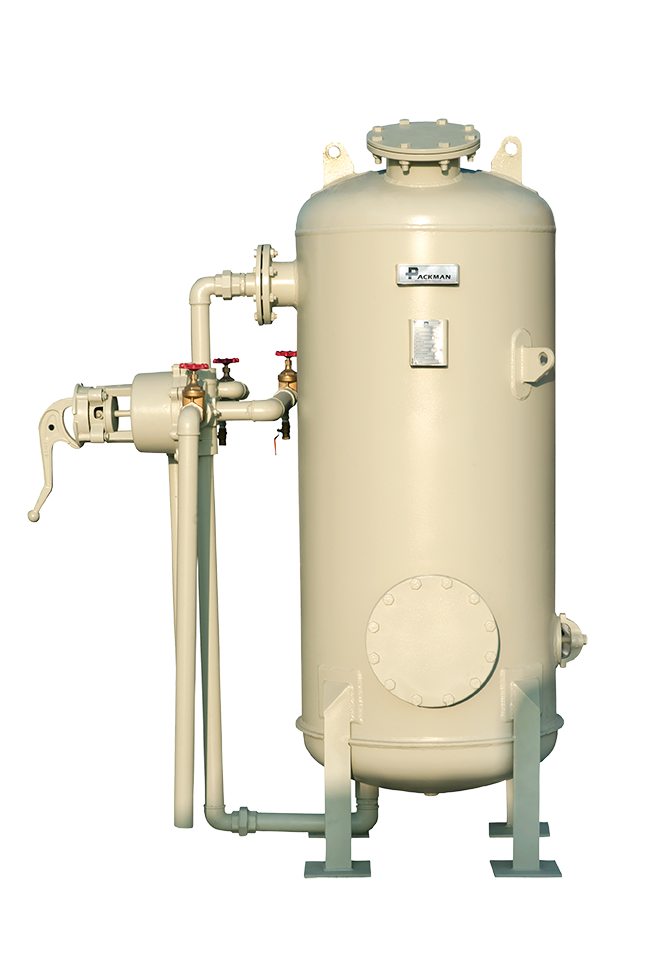

Heat Exchanger Pressure Vessel

Pressure Vessel Storage Tank

Storage Tank Scroll Aircooled Chiller

Scroll Aircooled Chiller Screw Aircooled Chiller

Screw Aircooled Chiller Air Handling Unit

Air Handling Unit Fancoil

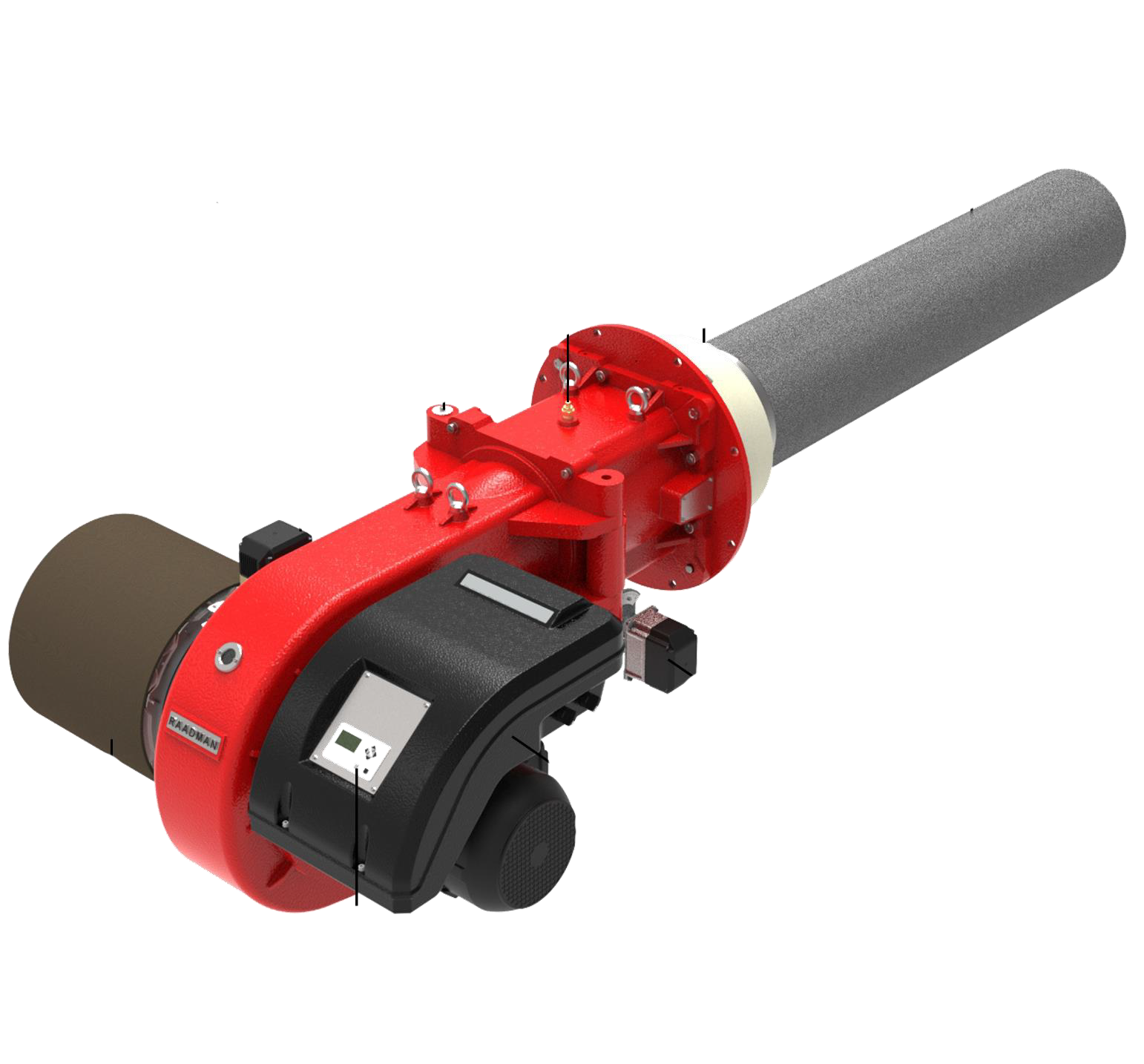

Fancoil Mono Block Burner

Mono Block Burner Dual Block Burner

Dual Block Burner Pre Mix & Semi Pre Mix Burner

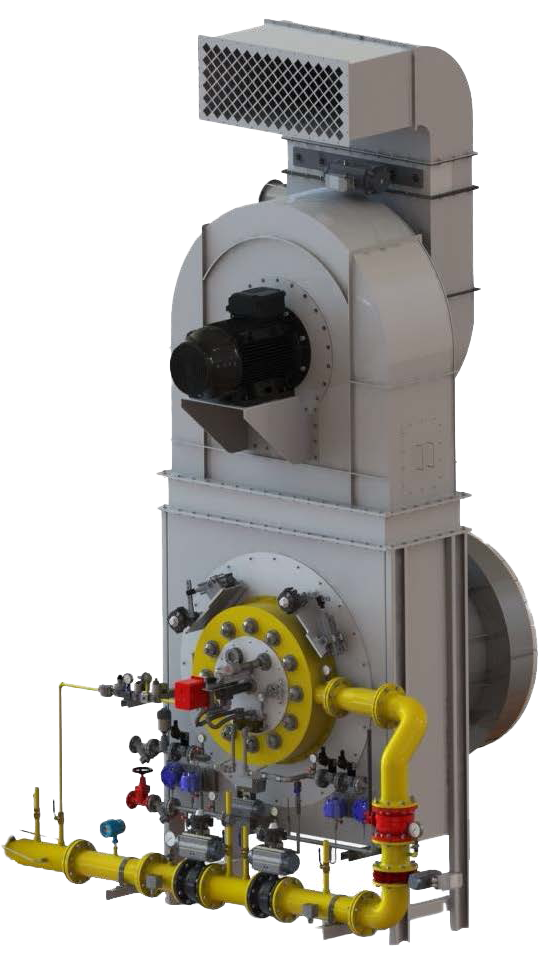

Pre Mix & Semi Pre Mix Burner Power Plant Burner

Power Plant Burner RO Water Desalination

RO Water Desalination Water Physical Filter

Water Physical Filter ION Exchange Filter

ION Exchange Filter Chemical Dosing Package

Chemical Dosing Package Heatco

Heatco Transheat

Transheat Planta

Planta Reco

Reco