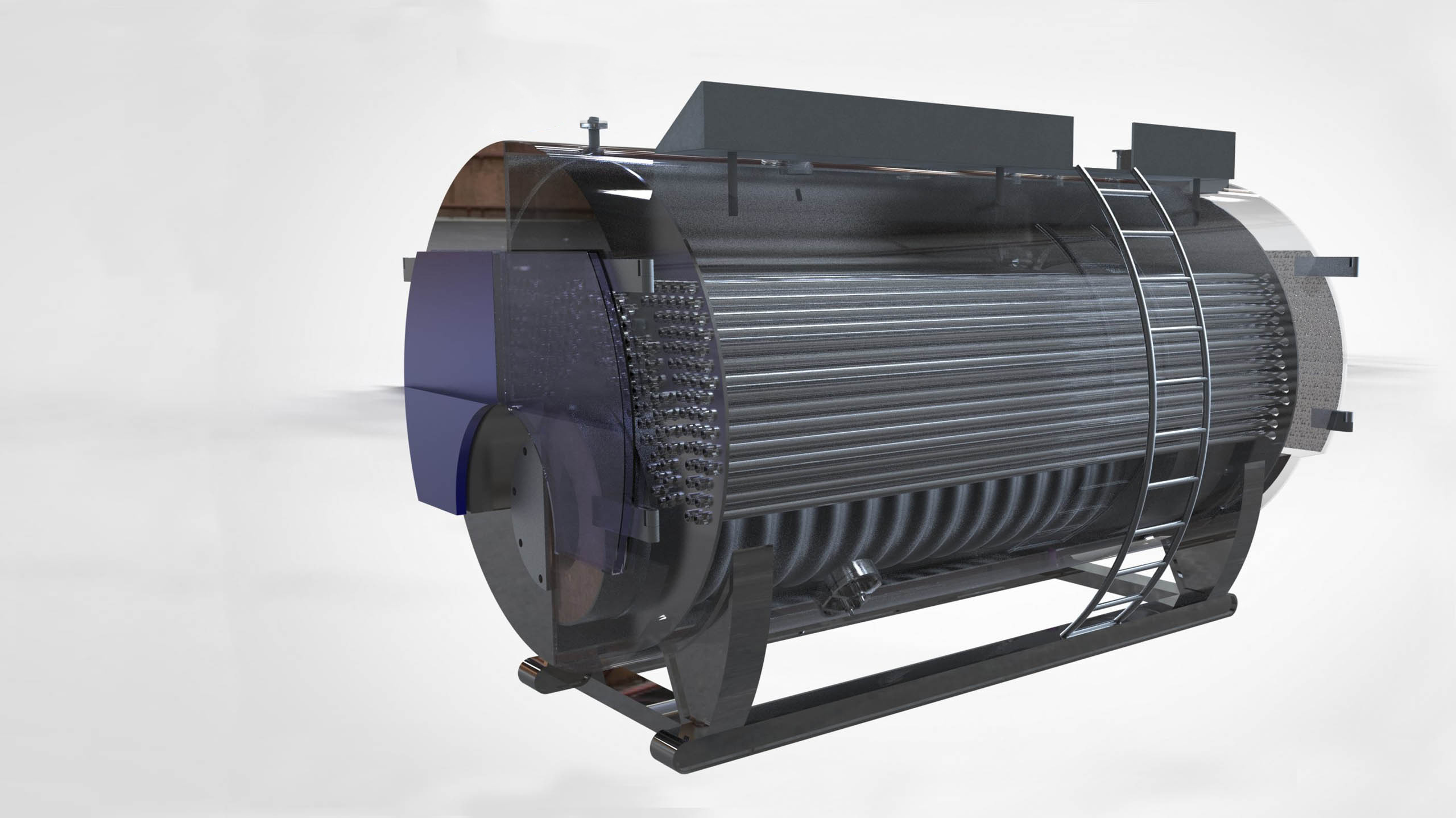

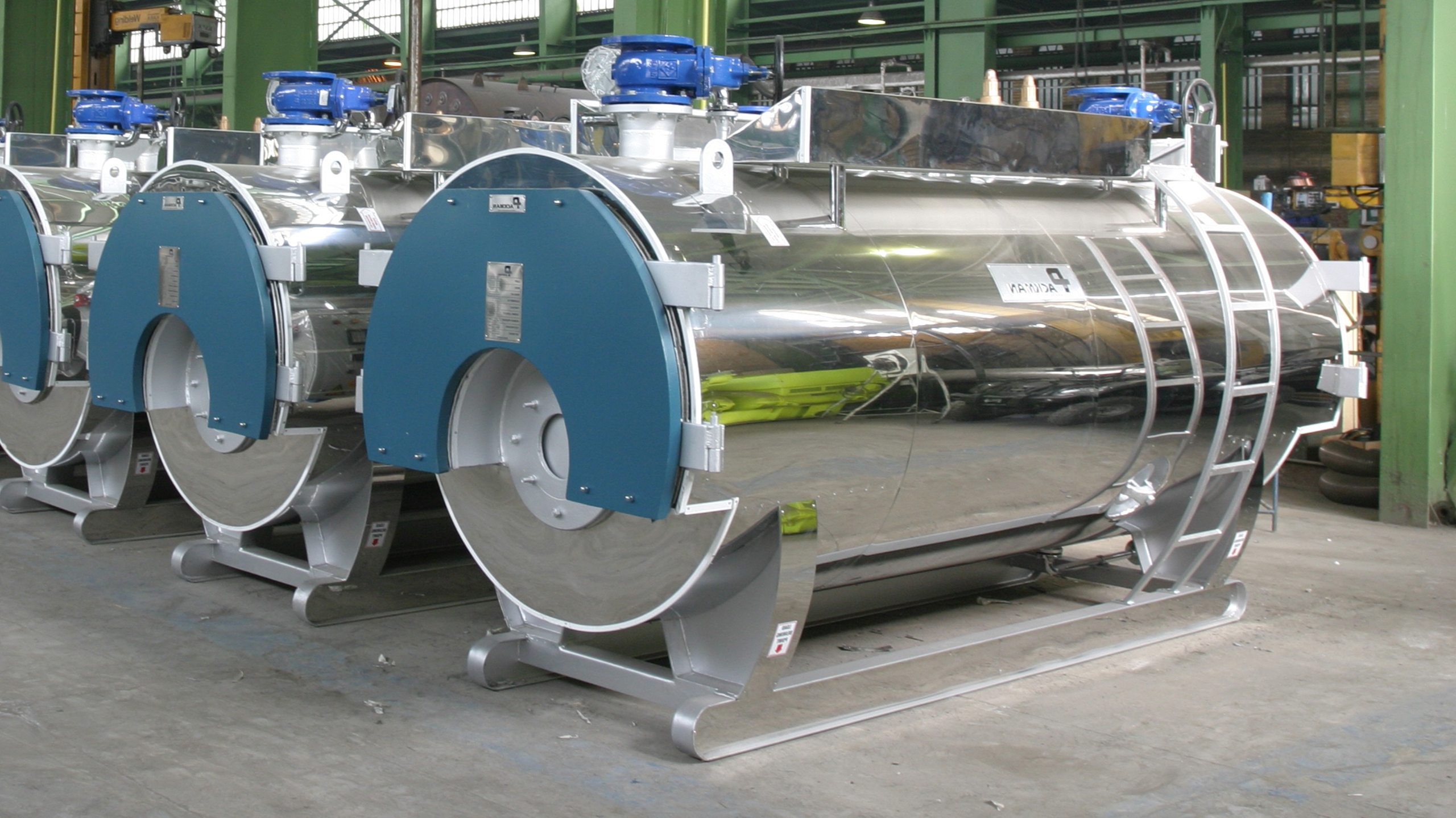

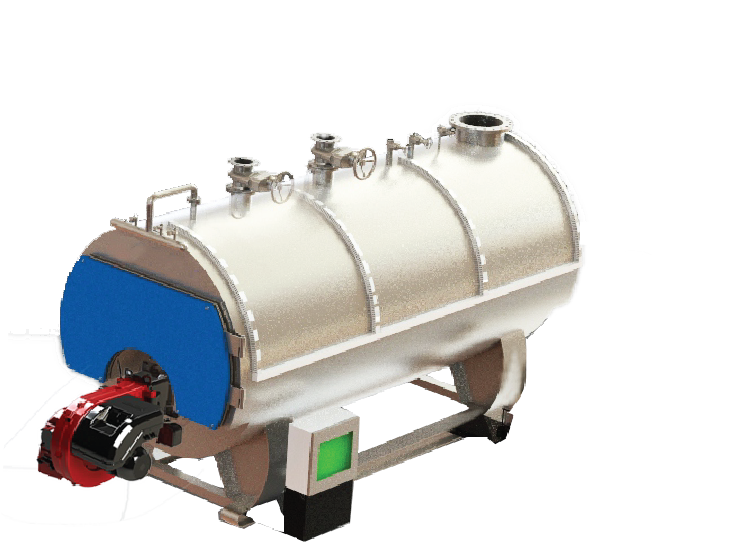

Three Pass Hot Water Boiler

Fire tube Wetback

Packman Company

Consumables and Equipment

High-quality European standard materials are used in the construction of boilers to increase the lifespan of the device.

Engineering & Designing

Designing state-of-the-art products is accomplished through modern technical knowledge and fluid and solid analysis.

Manufacturing and Production

Equipment production is carried out using the latest manufacturing equipment such as Four-Gun Roll Coaters, automatic Submerged Arc Welding machines for both powder and flux, Firetube Expander Rollers, and more.

After Sales Service

24-hour after-sales services are available in all cities of Iran to launch and ensure customer satisfaction.

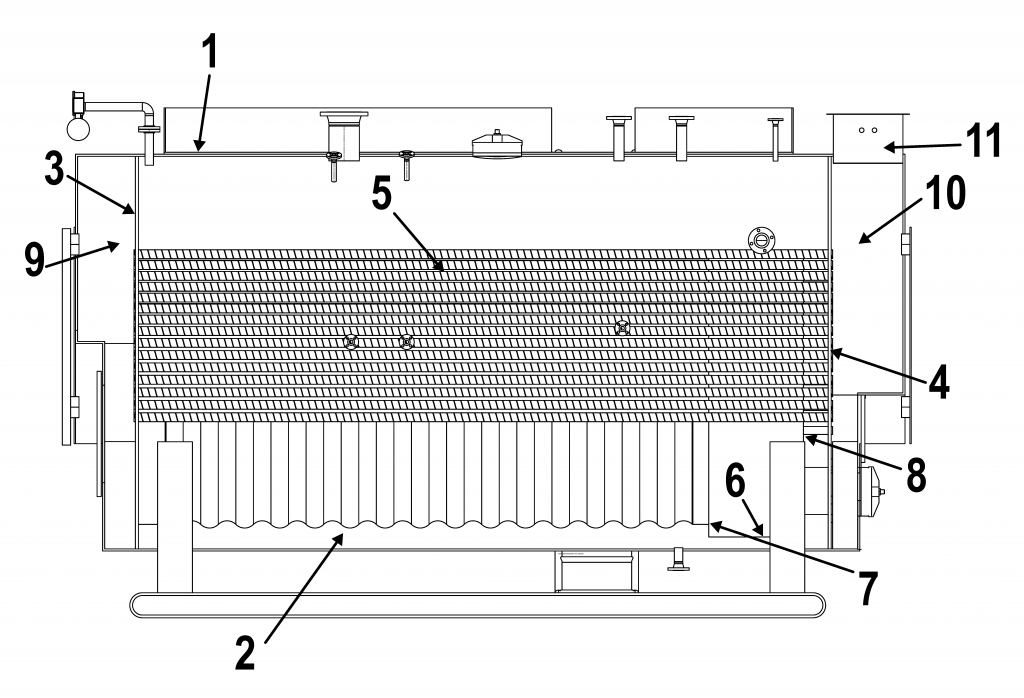

Cross-sectional view

Cross-sectional view

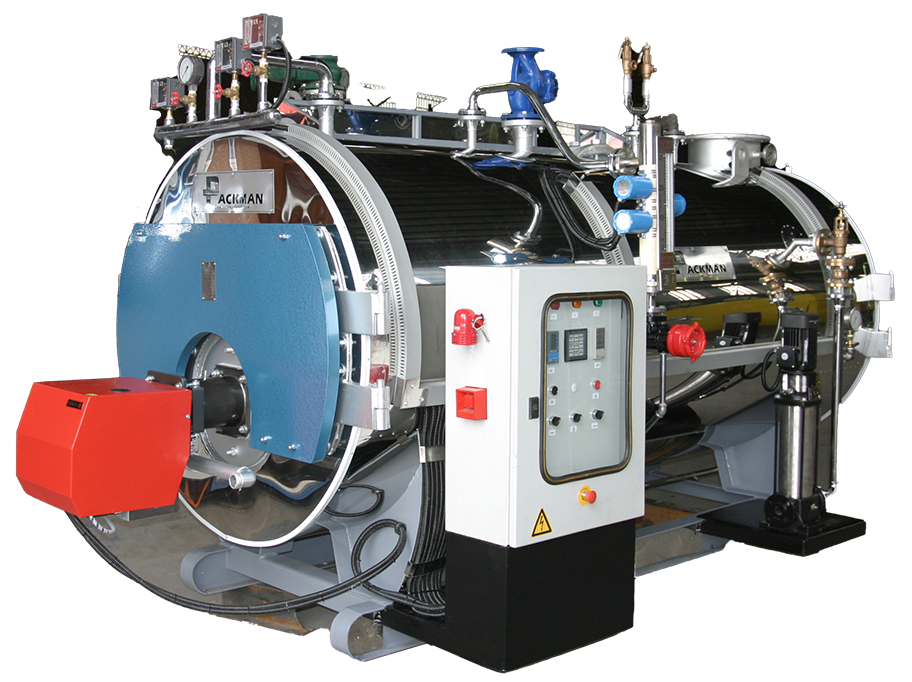

Completion facade

Completion facade

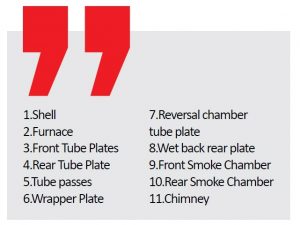

Packman Three Pass Hot Water Boiler Structure

Packman Three Pass Hot Water Boiler Structure

According to this plan, the hot gases created by the burner enter the first pass tube bundle after passing through the furnace and the return chamber (first pass), and after passing through them and reaching the front smoke chamber, they enter the second pass tube bundle (second pass) and after traveling the path and reaching the rear smoke chamber, they exit from the chimney..

Therefore, heat exchange between hot gases and water inside the device occurs through three parallel paths, hence this design is called “Three Pass”. Additionally, since one side of all major pressurized components of the machine is constantly in contact with water, the term “Wet Back” has been added to the name of this design to distinguish it from other types.

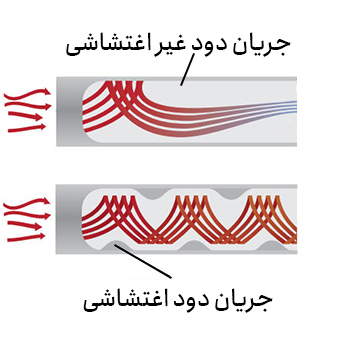

- Spiral pipe technology

- Intelligent control system of PLC type.

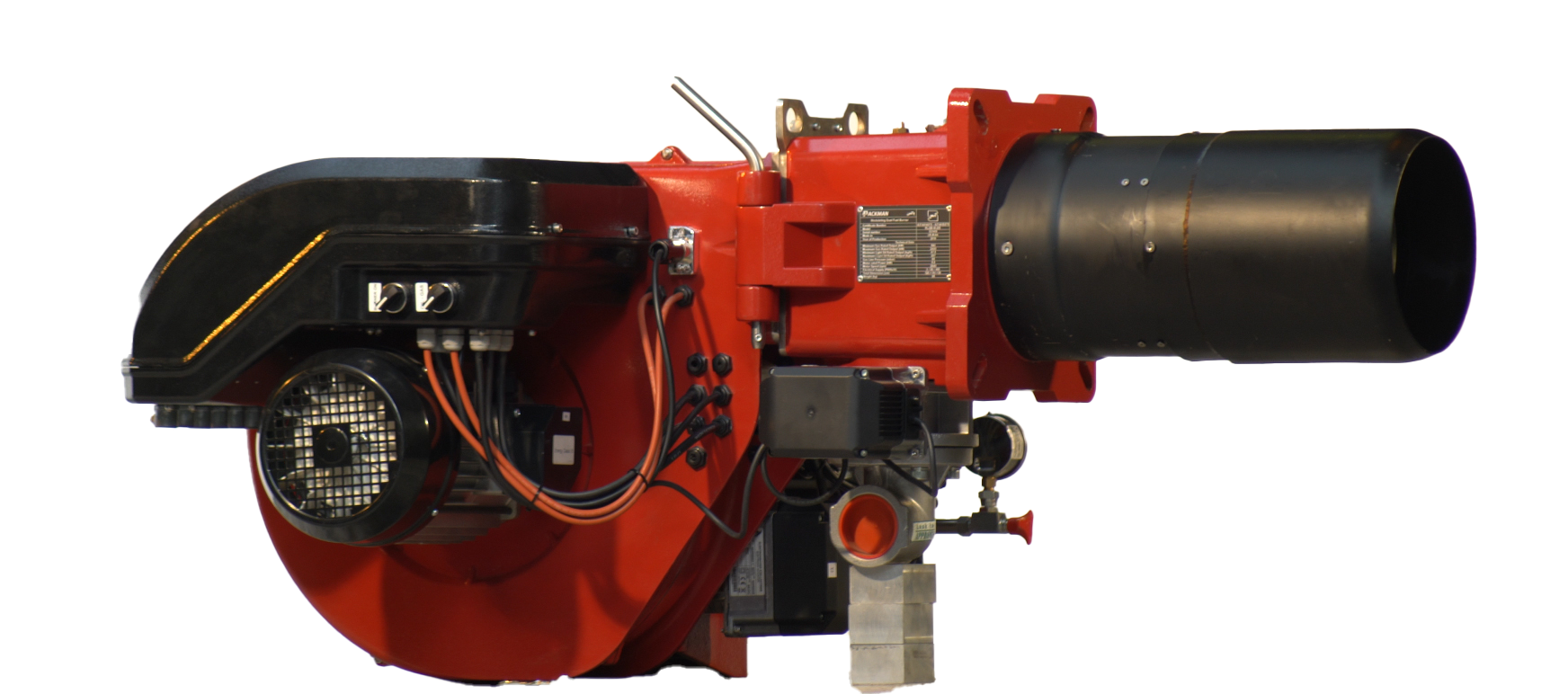

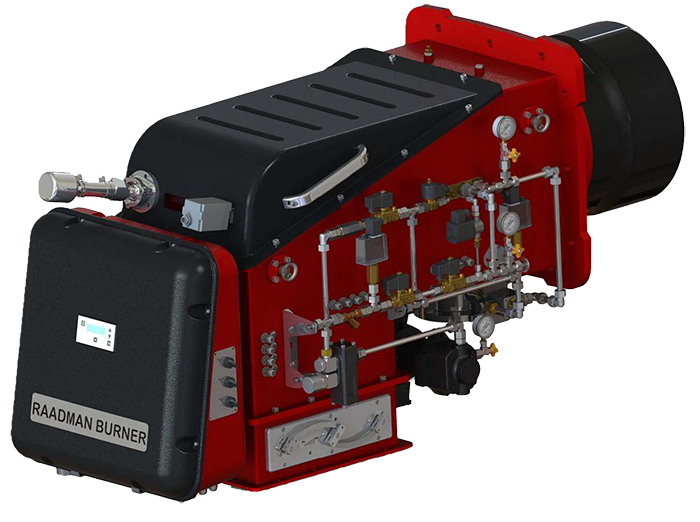

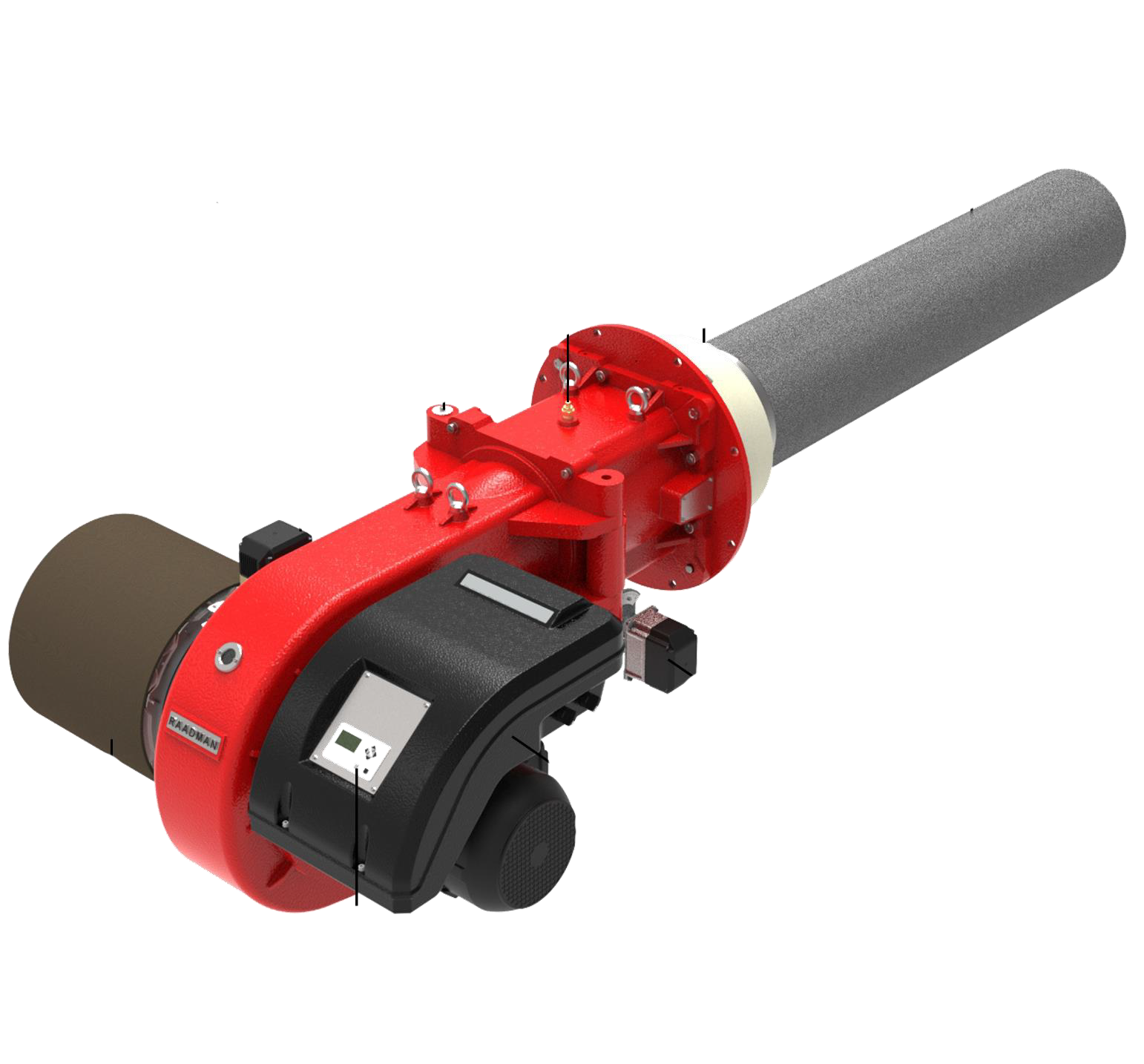

- The electronic modular burner Raadman

- Intelligent control system of PLC type.

Design, supply, and manufacture of equipment, as well as the installation of your hot water boiler room, leave it to us.

Welding tube machine

Some of the manufacturing and design features of Packman steam boilers include:

Spiral tubing improves smoke circulation in the third pass of boiler tubes, ensuring turbulent flow is maintained in the boiler and increasing heat transfer by up to 85 percent on an equal heat exchange surface.

Spiral Welded Pipe

Welding of different sections.

Packman's three-pass steam boilers range from 500 to 35,000 kilograms per hour.

Frequently Asked Questions

Some frequently asked questions have been set up for your convenience in selecting and obtaining further information. If you have further questions, please contact the technical department of the company.

?

In closed circuit systems, due to the lack of enough space to increase or decrease the volume of water, you must use an expansion source to control these changes.

Please note that to determine the capacity of your burner, you need the boiler output capacity, the combustion efficiency of the package, and the correction factor for the elevation above sea level at the installation site.. Keep in mind that “burner efficiency” or “boiler efficiency” on their own do not have any meaningful interpretation, and the manufacturer must specify the efficiency of the package based on the particular combustion system performance test..

Due to gas pipeline pressure, attention must be paid to the capacity and the declared number by the burner seller. In some capacities, gas pressure is low (less than 5 pounds per square inch), while in others, it requires pressure higher than this figure.

The recommended height limit for the steam boiler chimney is 6 meters, but it can be higher depending on factors such as capacity, diameter, friction rate of the chimney material, volume of combustion products, barometric pressure at the installation site, momentary pressure of combustion products exiting the nozzle, and fluid velocity. For detailed information, please contact the technical department of Pakman Company..

To obtain the catalog for Packman Company's three-pass steam boiler, click here.

Need more advise?

Do you know if you have free engineering consultancy and services on Packman products?

Boiler

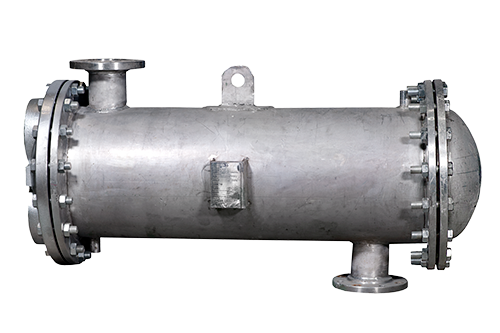

Boiler Heat Exchanger

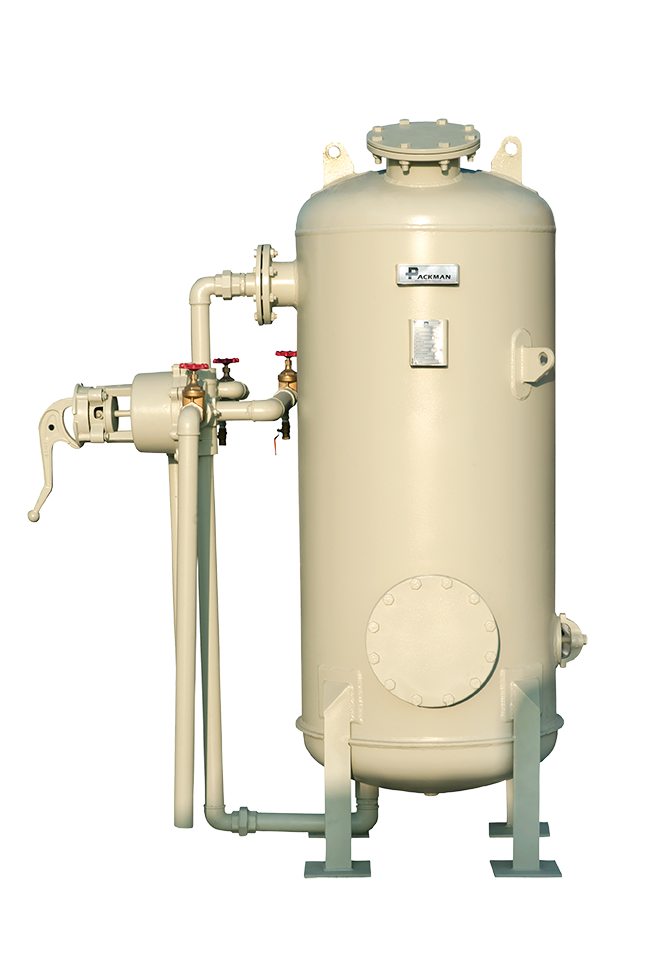

Heat Exchanger Pressure Vessel

Pressure Vessel Storage Tank

Storage Tank Scroll Aircooled Chiller

Scroll Aircooled Chiller Screw Aircooled Chiller

Screw Aircooled Chiller Air Handling Unit

Air Handling Unit Fancoil

Fancoil Mono Block Burner

Mono Block Burner Dual Block Burner

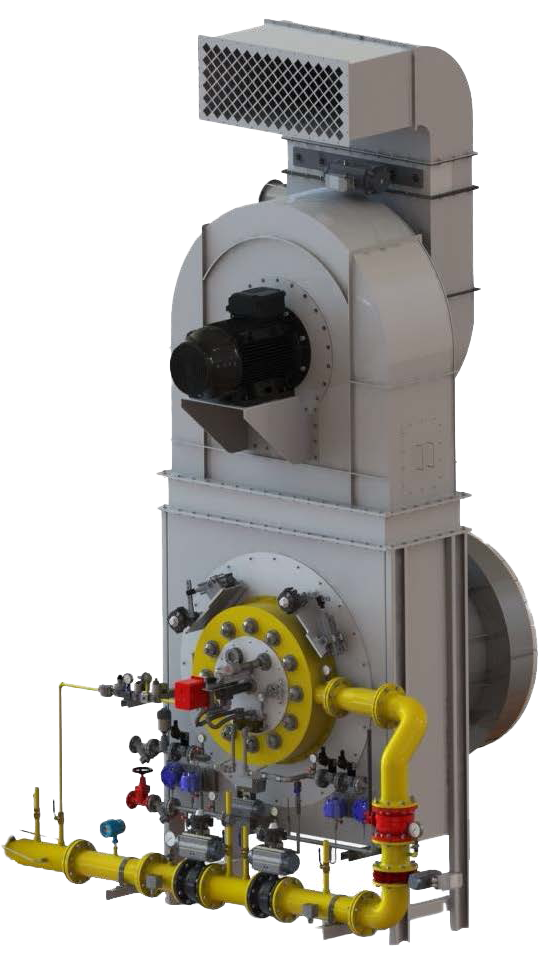

Dual Block Burner Pre Mix & Semi Pre Mix Burner

Pre Mix & Semi Pre Mix Burner Power Plant Burner

Power Plant Burner RO Water Desalination

RO Water Desalination Water Physical Filter

Water Physical Filter ION Exchange Filter

ION Exchange Filter Chemical Dosing Package

Chemical Dosing Package Heatco

Heatco Transheat

Transheat Planta

Planta Reco

Reco