100.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

150.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

200.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

250.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

300.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

350.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

400.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

500.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

600.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

700.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

800.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

900.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

1.000.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

1.250.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

1.500.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

1.750.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

2.000.000 kcal/hr Reverse Chamber Hot Water Boiler General Dimension

All dimensions are in millimeters

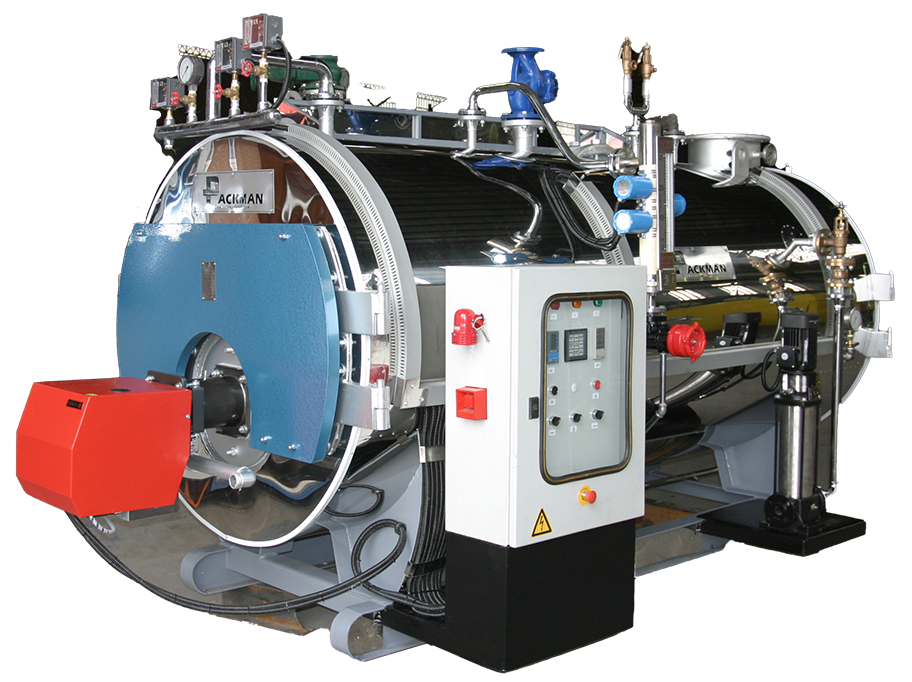

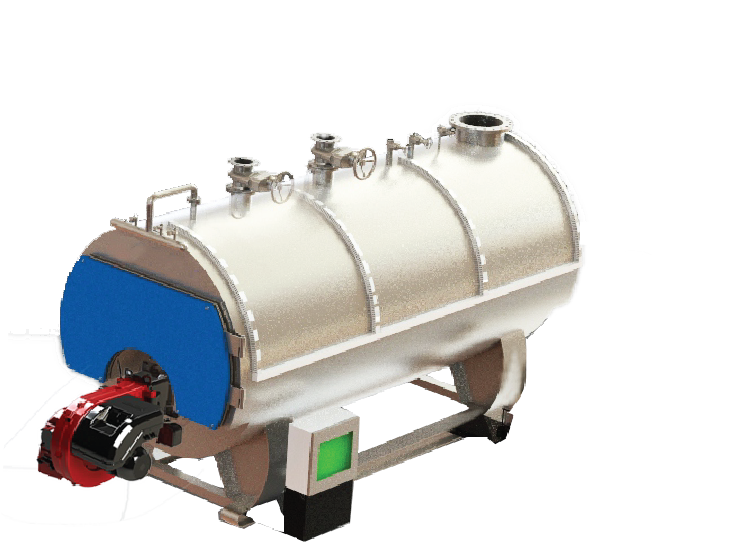

Boiler

Boiler Heat Exchanger

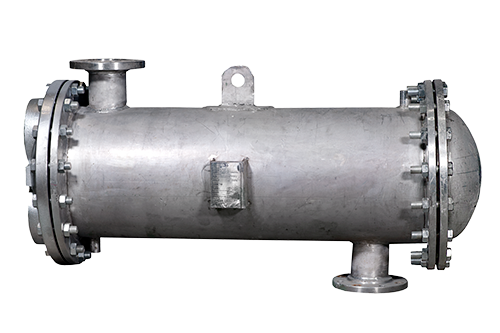

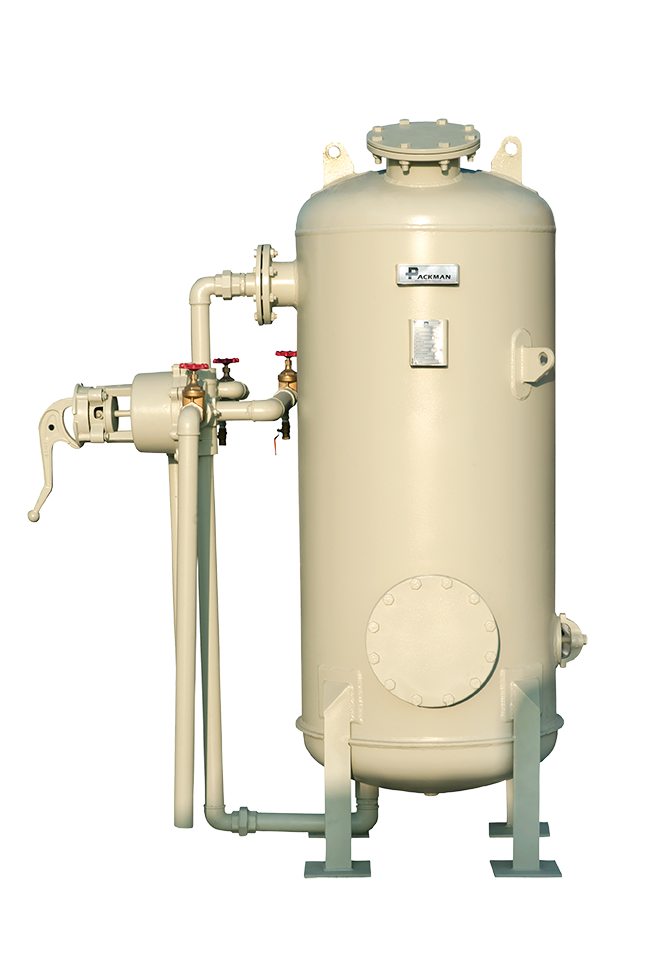

Heat Exchanger Pressure Vessel

Pressure Vessel Storage Tank

Storage Tank Scroll Aircooled Chiller

Scroll Aircooled Chiller Screw Aircooled Chiller

Screw Aircooled Chiller Air Handling Unit

Air Handling Unit Fancoil

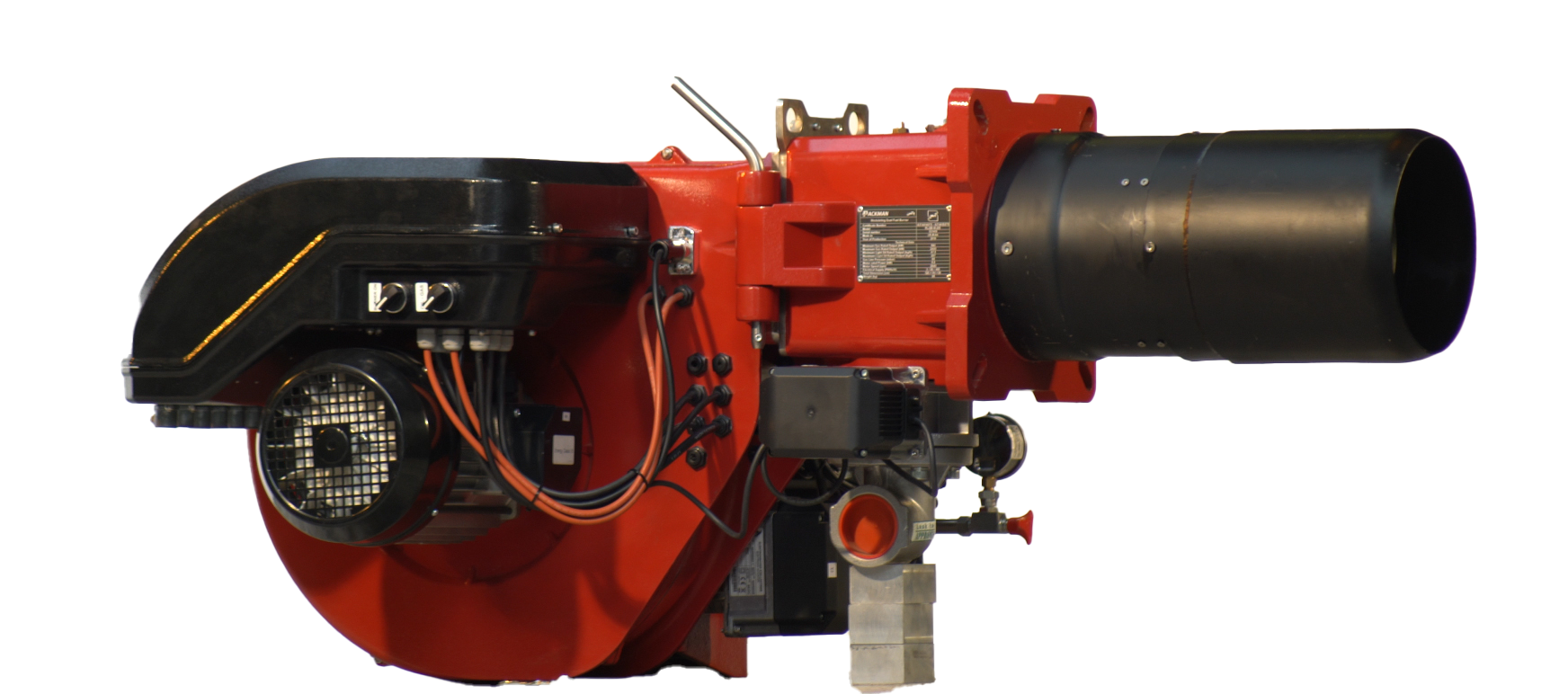

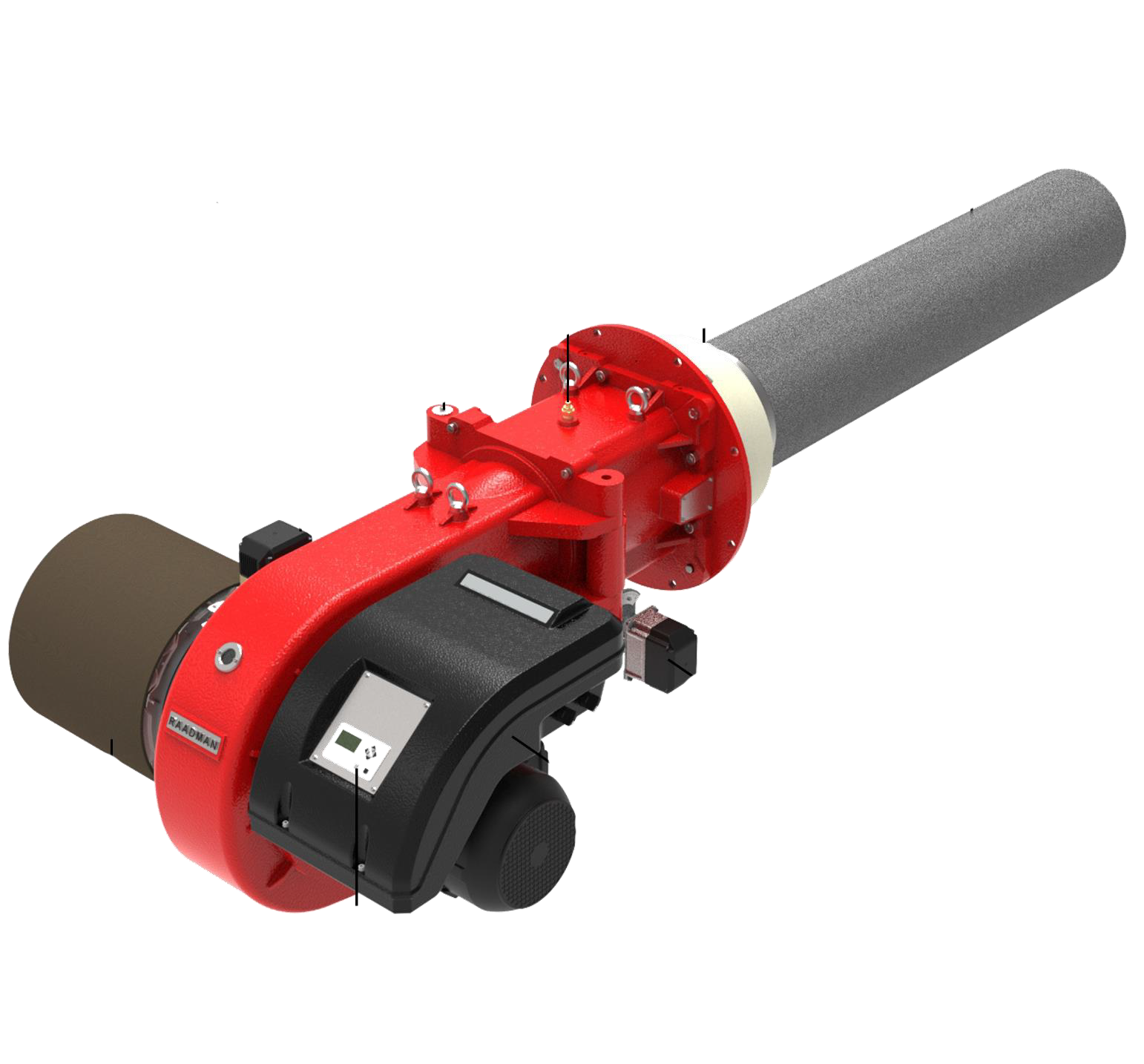

Fancoil Mono Block Burner

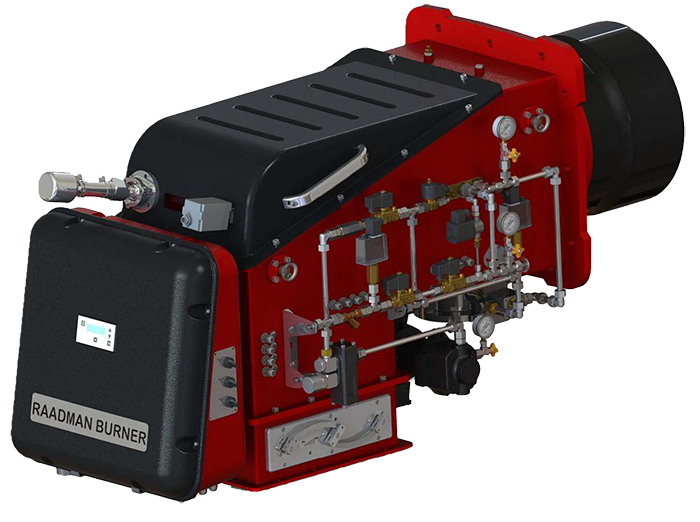

Mono Block Burner Dual Block Burner

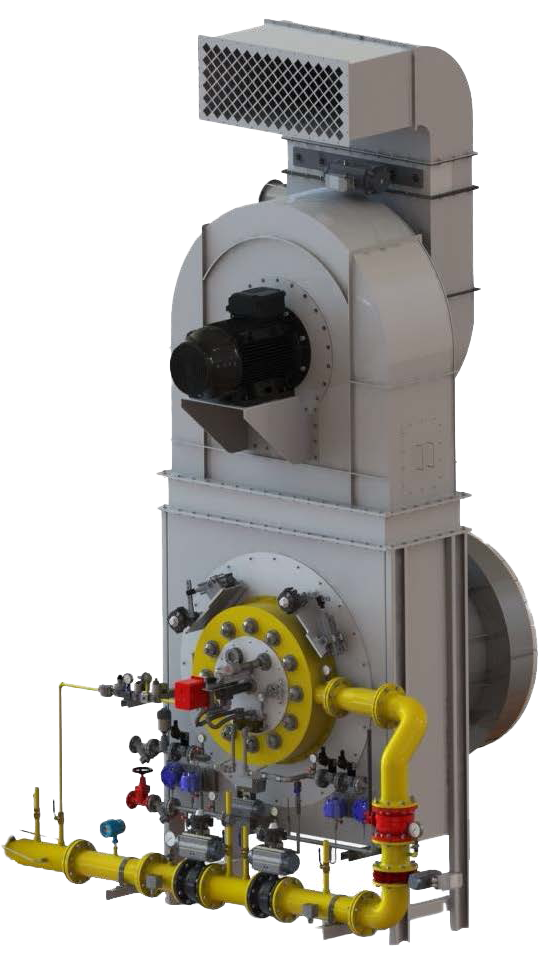

Dual Block Burner Pre Mix & Semi Pre Mix Burner

Pre Mix & Semi Pre Mix Burner Power Plant Burner

Power Plant Burner RO Water Desalination

RO Water Desalination Water Physical Filter

Water Physical Filter ION Exchange Filter

ION Exchange Filter Chemical Dosing Package

Chemical Dosing Package Heatco

Heatco Transheat

Transheat Planta

Planta Reco

Reco